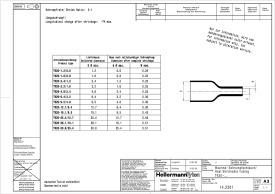

Heat Shrinkable Tubing 2:1 PVDF transparent 3.2/1.6

Art.-No. 311-00329

| TK20-3.2/1.6-PVDF-CL

|

Copied

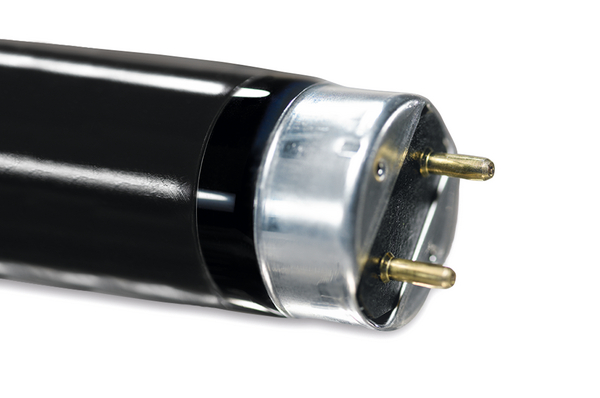

- Semi-rigid heat shrinkable tubing made of PVDF

- Thin wall and tough

- For higher temperature applications

- Very good mechanical strength, abrasion resistance and chemical resistance

- Meets various industrial standards

- Self extinguishing, UL 224 VW1 listed

More products in this product group:

| Application |

Typical applications of this translucent tubing are where high-temperature performance is required. Also very suitable for applications that ask for visual inspection of covered components, or if low friction surface is needed. TK20 is also used as oil stop for energy cables. This thin walled, translucent heat shrink tubing is often used for chemical applications. |

| Behaviour At Low Temperature | not cracking |

| Behaviour at Heat Shock | not cracking, not dripping, not fluid |

| Behaviour at low Temperature test method | SAE-AS23053 |

| Colour | Transparent (CL) |

| Elongation At Heat Aging | 200% |

| Heat Aging Test | 168h/250°C |

| Heat Aging test method | ASTM D638 |

| Heat Shock Test | 4h/300°C |

| Key product features | high temperature resistant, chemical resistance |

| Material | Polyvinylidene Fluoride (PVDF) |

| PART DESCRIPTION | TK20-3.2/1.6-PVDF-CL |

| Pack Content | 125pcs. |

| Package Content packed in | pcs. |

| Printable | No |

| Product Family | TK20 |

| Product Group | Heat shrinkable tubing 2:1 - PVDF |

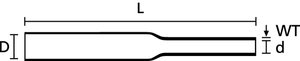

| Shrink Ratio | 2:1 |

| Size | 1/8" |

| Type | TK20-3.2/1.6 |

| Variant | Thin-Wall |

| With inner glue (Yes/No) | No |

| Designation as per VG-Norm | VG 95343 T05 F 004 M |

| Dielectric Strength | 30kV/mm |

| Dielectric Strength test method | SAE-AS23053 |

| ELV compliant (Article 4 - 2) | YES |

| Elongation at break | ≥350% |

| Elongation at break test method | ASTM D882 |

| Flammability | UL 224 VW-1 |

| Halogen-free | No |

| Hazardous Goods | No |

| Insulation Class | F (VDE 0530) |

| Min. Shrink Temperature - °C | +170 °C |

| Nato number | 5970-12-158-4282 |

| Operating Temperature | -55 °C to +175 °C |

| ROHS compliant | Yes |

| Self extinguishing | Yes |

| Specifications | ANSI/UL 224, VG 95343-5:2016-10 |

| Specifications |

|

| Tensile Strength | 40MPa |

| Test Method Tensile Strength | ASTM D412 |

| UL OCD link | Link |

| UL Recognized (US) | Yes |

| UL-File Number | E198023 |

| Volume Resistance | 10¹⁵ Ω cm |

| Volume Resistance test method | ASTM D876 |

| Water Absorption | 0.2% |

| GTIN-13 / EAN | 4031026223773 |

| Packaging 1 - Height (m) | 0.015m |

| Packaging 1 - Length (m) | 1.27m |

| Packaging 1 - Qty | 125 |

| Packaging 1 - Type | bag |

| Packaging 1 - Volume (m³) | 0.00295275m³ |

| Packaging 1 - Weight (kg) | 0.38325kg |

| Packaging 1 - Width (m) | 0.155m |

| Packaging 3 - Height (m) | 0.15m |

| Packaging 3 - Length (m) | 1.27m |

| Packaging 3 - Qty | 750 |

| Packaging 3 - Type | carton |

| Packaging 3 - Volume (m³) | 0.0248m³ |

| Packaging 3 - Weight (kg) | 2.9kg |

| Packaging 3 - Width (m) | 0.13m |

| Packaging 4 - Length (m) | 1.2m |

| Packaging 4 - Type | pallet |

| Packaging 4 - Width (m) | 0.8m |

Argentina

Argentina Australia

Australia Brazil

Brazil Bulgaria

Bulgaria China

China Czech Republic

Czech Republic Denmark

Denmark Finland

Finland France

France Germany

Germany Hungary

Hungary India

India Italy

Italy Netherlands

Netherlands North America

North America Norway

Norway Poland

Poland Portugal

Portugal Romania

Romania Russia

Russia Singapore

Singapore Slovenia

Slovenia South Africa

South Africa South Korea

South Korea Spain

Spain Sweden

Sweden Switzerland

Switzerland Türkiye

Türkiye United Arab Emirates

United Arab Emirates United Kingdom

United Kingdom

다운로드

다운로드

H6100

391-00110

H6100

391-00110 TK20-1.6/0.8-PVDF-CL

311-00169

TK20-1.6/0.8-PVDF-CL

311-00169