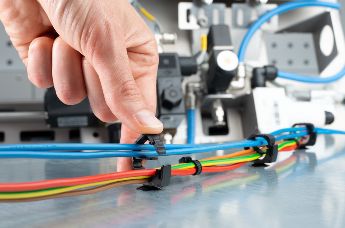

Cable clips are used to secure and organise wiring in various applications. They are typically designed with a clip or open-head design mechanism and can be attached to various surfaces. Cable clips prevent tangling as well as trip hazards and ensure a neater and more organised appearance.

The HellermannTyton cable clip portfolio includes cable clips with many options for closure type, bundle direction and different diameters: adhesive cable clips, screwable cable clips, edge-mount cable clips, connector clips and bundling clips.

Adhesive cable clips are easy to mount because they do not require nailing or screwing in place and therefore have no impact on the statics. They are designed for low energy surfaces. Other advantages include a reduced risk of corrosion and significant weight reduction compared to mechanical mounting.

HellermannTyton uses different types of acrylic or synthetic rubber adhesives for self-adhesive cable clips. These differ in the operating temperature range and the pull-off force of the adhesive.

Acrylate- based adhesive clips:

Synthetic rubber-based adhesive clips :

Once the self-adhesive cable clip is in place, the cable bundle can be positioned in the clip. Some clips are open at the side and hold the cables and wires by means of an inwardly directed retaining nib, or by a planned narrowing of the clip geometry. This makes it very easy to add, remove and replace cables at a later stage.

The clips are affixed by peeling off the protective background and sticking them to the desired surface, including plastic and metal. Once the adhesive wire clip is stuck in place, the cable tie can be fed through the slot and the cable bundle can be positioned inside the tie. Finally, the wire bundle and cable tie are secured to the mount by closing the cable tie.

The RA and RB cable clip series are one-piece self-adhesive mounts which can be used without an additional cable tie. They are made from PA66 with synthetic rubber adhesive.

RB-series self-adhesive clips offer great routing freedom and also reduce the risk of corrosion compared with screw fixing mounts. They are ideally suited for tool-free installation and can be re-opened as well as reused easily when cables need to be replaced. The RB series is available in bundle diameters from 5.0 up to 14.0 mm.

The RA clips are ideal for use in applications that are difficult to access, or for areas in which self-adhesive is the only possible fixing method. This comes in handy in scenarios where self-adhesive is the only possible fixing method. They are most commonly found in industries such as automotive, bus and truck, construction vehicles or industrial buildings. The RA series is available in bundle diameters from 3.0 up to 18.0 mm.

HellermannTyton offers adhesive wire clips specifically designed to hold cables, tubes and conduits without using a cable tie. These cable clips can simply be screwed or stuck onto panels. The side gripping fingers allow for easy cable removal while at the same time holding onto them firmly. The TY8H1S cable clips are commonly used in computer equipment, gaming machines and domestic appliances.

Magnetic cable clips are a versatile and efficient alternative to traditional cable management solutions, offering tool-free installation without compromising the integrity of the mounting surface. These clips are ideal for dynamic environments or temporary setups where configurations change frequently, making them perfect for industries that demand flexibility and precision.

Unlike adhesive or screwable clips, magnetic cable clips leave no sticky residue or holes. They can be repositioned or removed without affecting the surface, ensuring a clean, professional installation every time. Plus, with no adhesive drying time or tools required, magnetic clips significantly reduce installation time, improving workflow and saving labour costs.

Magnetic cable clips are available in three versions:

• MAGMB-series: Available in two different base sizes, offering a range of vertical pull forces for different applications

• MAGRB-series: Suitable for bundle diameters from 5.0 to 8.0 mm, ideal for smaller cable configurations

• MAGRA-series: Designed for bundle diameters from 3.0 to 13.0 mm, providing versatility across different industries and setups

Cable holders from HellermannTyton are types of cable-mounting or fastening devices that require screws or fastening elements to securely attach cables or wires to a specific surface. This type of cable holder can be made of either plastic or metal, as in this case. Besides this screw element, it features one or multiple openings where the cables can be inserted to keep them in place. Cable clips with screws are often used where heavy cable bundles need to be supported.

One type of screwable cable clips HellermannTyton offers are the D-clips. D-clips in cable management typically have a shape resembling the letter "D," hence the name. They usually feature a curved or semi-circular design with an open side. By merely pressing cables into the open side of the clip, they offer a swift and efficient way to organize wires, ensuring significant time and cost savings in cable maintenance and setup.

D-clips offer a flexible grip, allowing for the convenient removal and replacement of cables whenever needed. Due to the application method of screwing and the POM (polyacetal) material used here, these parts are used wherever mechanical loads are present, e.g., in house, office, and industrial warehouse construction.

Additionally, owing to their durable and robust form under different temperatures and humidity conditions, such products are utilized in areas with high precision requirements, such as the automotive, electronics, or medical technology sectors. HellermannTyton offers screwed D-clips in three sizes and with three different bore diameters.

In the HellermannTyton portfolio, other cable clips that need to be screwed in include P-clips (also known as P-clamps). They typically consists of a metal or plastic clamp that is shaped like the letter "P" when viewed from the side. This design allows for easy insertion and secure holding of cables, wires or even pipes, providing an organized and stable routing system while preventing movement or potential damage due to vibration or other factors. P-clips are commonly used in various industries such as automotive, electrical, aerospace, and industrial applications.

HellermannTyton offers different kinds of cable clips for parallel and multiple routing of tubes, hoses, or pipes. These hoseclips allow bundles to be held closely together without getting entangled or twisted. They can easily be assembled by hand and offer a firm hold.

Hose clips for parallel routing are available with two or three chambers. The clips for parallel routing also come with fir tree foot parts for fixing in pre-drilled panel holes. Once installed, the hose simply snaps into the clip and can be removed and reinstalled without removing the clip.

Bundling clips can be fixed to the wire harness with cable ties or adhesive tape. There are different application options including products for holes, edges, bolts, or simply for adhesive-taping, bundling, with spacers, or a harness clip for multiple routing. Bundling clips are widely used in the automotive industry but can also be used in any application to provide stability and support to longer cable harnesses and wires.

The SOC5FT6LG bundling clip is one of the most popular HellermannTyton clips. It is made for a round 6.5 - 7.0 mm hole and hexagonal 6.1 - 6.6 mm hole and features an offset spacer. The side slots on the bundling bar are ideal for fixing the cable harnesses or wires with a cable tie or adhesive tape. The cable fits snugly into the slightly curved bundling bar.

Magnetic detectable cable clips are specialised clips or fasteners designed to secure and organise cables, wires, and other electrical components in various industrial and commercial applications. These clips offer unique benefits and use cases, primarily focused on safety in environments where foreign object debris (FOD) and foreign material exclusion (FME) are critical concerns. They are most commonly used in settings where the integrity of products, equipment or processes is essential – for instance the food processing and pharmaceutical industries with strict hygiene standards.

Magnetic detectable cable clips ensure that no foreign materials from the cable management system contaminate the products. The magnetic properties of these clips make them detectable using magnetic scanning equipment, metal detectors, or X-ray machines. This feature enables quick and reliable identification and removal of lost or misplaced cable clips. Magnetic detectable cable clips come in various sizes and designs to accommodate different cable diameters.

High voltage clips are commonly used on electric vehicle wiring harnesses. The robust protective cover with a ribbed design provides extra strength. The soft inserts cushion the cables and wires. The shell of these high voltage cable clips are made from PA46 or PA6HS and the soft inserts from AEM or EPDM.

High voltage cable clips are available as two-piece parts which simply click together for easy installation without tools, or as one-piece parts with hinge or twist lock closing options.

HellermannTyton provides cable clips for use in fluid management wherever fluid-carrying lines and hoses need to be securely fastened – also with movement compensation. This also includes cable clips that can be reopened and reused for maintenance.

Cable clips, also known as cable clamps or cable organisers, are small devices or accessories designed to secure and manage cables, wires, leads, hoses or conduits in a neat and manner. They are available with various attachment options for different surfaces and prevent tangling, reduce clutter, and enhance safety by keeping cables in place and preventing them from becoming trip hazards.

Installing cables clips is a straightforward process as they are easy to assemble by hand or conventional tools like a screwdriver. The method depends on the type of cable clip and the surface that you are attaching it to.

The right size clip is dependent on the diameter of the cable(s) you are trying to manage and your choice of the type of cable clip for your application needs. In order to determine the appropriate size, consider the following:

Cable clips come in various designs. The most common ones are plastic clips that have a tab or locking mechanism holding the cable in place. In order to pry a cable clip open, you will need specific tools. Adhesive cable clips can be pried off.

Most cable clips are single-use and cannot be reused after removal as they will not meet initial locking performance requirements. For applications with the need for maintenance or conversion, make sure to use a cable clip that can be reopened or is lockable.