EDI stands for “electronic data interchange” and can be imagined as a “translator” that mediates business processes such as ordering, delivery and invoicing between different systems.

The following looks at key features and advantages of using EDI with HellermannTyton as part of our e-business.

EDI – Your OPEX game changer in solar plants

Discover the ways in which you can streamline your purchasing for solar plants with electronic data interchange (EDI).

EDI in a nutshell

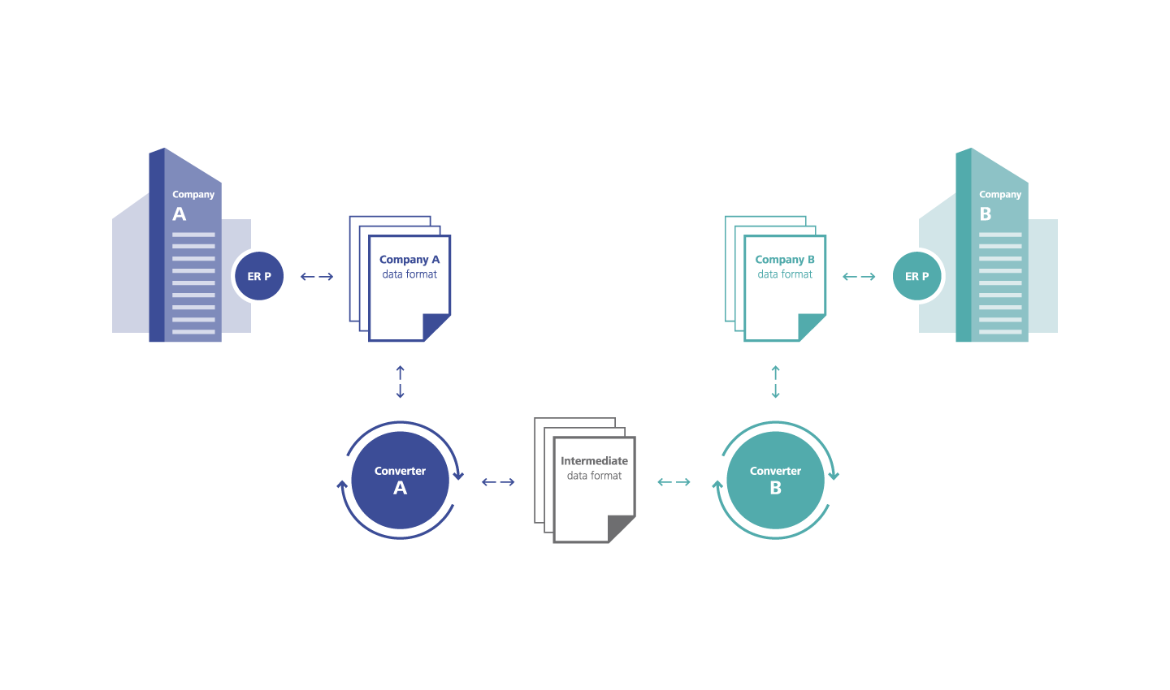

EDI “translates” certain information between otherwise unlinked systems. The information is standardised by converters so that it can be shared across different systems. It therefore automates manual processes.

So if you want to order, say, edge clips from us to fix cable to the frames of solar panels, EDI acts as a translator between your purchasing system and our supplier system. We talk in an “agreed language” both systems understand.

Do I need special software for this?

Yes. The most direct method is peer-to-peer software. If you’re using enterprise resource planning (ERP) software, it hooks into this and communicates with us based on conversion to certain standards. There are different business models and software, but a good provider will walk you through EDI options.

Wait a minute, does that mean you get to see everything?

No, the companies agree on what information is exchanged. For example, you might want to communicate an order to us for a quantity of EdgeClip MSC2 retainers to secure cable to the side of your panel. Invoicing and delivery details, for instance, become visible to both of us. Defining what information is exchanged is an important part of setting up EDI.

Okay, so what changes exactly once my company starts using the software?

You can conduct orders for your solar installation directly on an e-business basis, and selected “paperwork” is digitally transferred between us and visible to both of us.

What are the advantages for me?

Cost and speed are the bottom line, because you're automating your data. But it also makes purchase-to-pay processes more efficient. And it can improve the quality of data, because it's automated and human error is reduced.

Are you sure this is going to reduce the OPEX of my solar plant?

Yes, because ordering, delivery and invoicing processes take time and are all part of your OPEX in a solar installation. If you look at your OPEX holistically, you’ll see many benefits in this regard.

Wait a minute, we’re already using EDI. So what’s new?

All the better. But if you’re not using EDI with us, it’s time to start.

But I like personal contact with your Team Sunshine. Does that change?

Nothing changes in that regard. EDI is for backend business processes. Our Team Sunshine members are first and foremost experts in solar plants and cable management. They’re always talking to installers and operators offering help, often on-site. Nothing changes in that regard, except your backend processes become more efficient.

If you want to find out more, Woyb is one company that specialises in EDI and has an informative website.

Contact our experts

Are you interested in finding out more?

Our experts are always ready to offer help and advice, and answer any questions.