From detectable cable ties and easy-to-clean PVC tubing, to corrosion-resistant identification tags, HellermannTyton provides innovative product solutions for the food industry.

The extensive product portfolio reflects our long-standing industry expertise. HellermannTyton has provided outstanding product quality and has met the high requirements of various industries for over 75 years.

In food production with open production processes it is advisable to use materials that are easily detectable. HellermannTyton offers plastic and stainless steel products that are simple to detect. They make an important contribution to quality management for the food industry, particularly when following the HACCP approach.

Our detectable products support you in the realisation of your HACCP approach. You can find a selection of metal content products here.

Requirements for high-quality food production processes are high. All the product solutions presented here therefore conform to REACH Directive (EC) no. 1907/2006 and are DEHP-free (Bis(2 ethyl(hexyl)phtalat), a plasticizer deemed to be toxic for reproduction.

When new machines are installed, or production lines modified, many cables and wires have to be bundled – from the outset. MCT Series cable ties consist of a special polyamide compound and are interfused with metal pigments. Even fragments can be detected if they find their way into the production process by accident. Contamination from plastic cut-offs can consequently be reduced significantly. The MCT Series was developed together with large manufacturers of foodstuffs.

In addition, the MCTS variant is particularly suitable for use with saline solutions or in salt environments. Corrosion-resistant stainless steel fibres are used in these products.

As an ideal supplement to our detectable cable ties, we also offer a variety of detectable mounts. These include our MCMB- & MCCTAM series. All our mounting bases with metal pigments or stainless steel fibers are detectable and meet the high standards of the food industry.

Important for your quality management in the food industry:

Further information on MCT/MCTS Cable Ties can be found here.

High temperatures and substantial mechanical loads are not uncommon in food production processes. MBT Cable Ties from HellermannTyton are the best choice for rock-solid fastening. The patented metal ball-locking head of the MBT Cable Tie consists of one or two metal balls and a forked band end that makes threading easy. P Mounts compliment the MBT perfectly.

The MBT Cable Ties are made of high-grade stainless steel and withstand acids and salt water as well as temperatures up to +538 °C, providing the safety and peace of mind necessary in food production.

Important for your quality management in the food industry:

Further information on MTB Cable Ties can be found here.

Hygiene requirements and cleaning standards in the food processing industry are stringent. E/TFE Cable Ties are an excellent solution for quality management in the food industry on account of their resilience to chemicals such as corrosive cleaning fluids and disinfectants like hydrogen peroxide (H 2O 2).

They can be comfortably handled manually or - to ensure reliable application - with the help of tools.

Important for your quality management in the food industry:

Further information on E/TFE cable ties can be found here.

The PSRSC Protective Conduit conforms to European directive 10/2011 for plastics that come into contact with foodstuffs. Together with PSR Plastic Screw Connectors and PSRSC Metal Screw Connectors, they meet the requirements of the food industry to first-class standards. The smooth outer and inner walls of the PSRSC Conduit allow quick and easy cleaning and simple cable feeding.

Important for your quality management in the food industry:

Further information on PSRSC Protective Conduits can be found here.

HellermannTyton label products can be used to safely identify food production equipment. According to the ISEGA Institute, the adhesive for material types 1101, 1102, 1103, 1204, 1206, 1207, and 1210 can be used safely for label production. It is also proven to be suitable when the adhesive layer is in indirect contact with foodstuffs.

Important for your quality management in the food industry:

Non-corrosive M-BOSS stainless steel markers are ideal where temperatures and/or chemical substances have a damaging effect on identification in food production facilities.

Important for your quality management in the food industry:

Further information on M-BOSS Marker Plates and the M-BOSS System can be found here.

Detectable products are an essential requirement in the food industry. In production or during cleaning, plastic products used for bundling, fastening and protecting cables and wires on food processing machines, leading to the machines or in the plant surroundings itself, can enter into the food or beverage mass. Such contamination must be swiftly detected and removed.

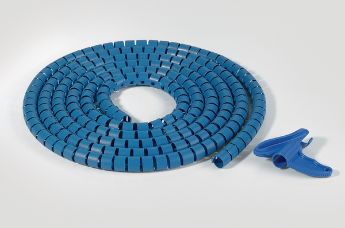

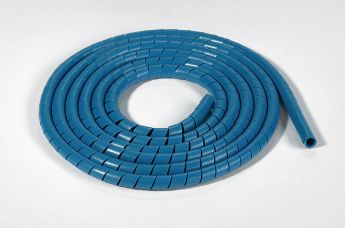

Due to its high metal-content (about 14 %), even small bits of SBPEMC spiral binding or HWPPMC Helawrap are detectable with standard detection equipment, as has been shown by testing conducted by HellermannTyton. Nonetheless, SBPEMC and HWPPMC retain their flexibility as well as ease-of-application and protect cables as effectively and safely as our standard spiral binding and Helawrap products. Moreover, like our metal-content cable-ties and fastenings, SBPEMC and HWPPMC are manufactured in the colour blue to enhance visibility.

SBPEMC and HWPPMC are targeted to the food- industry and its suppliers of food-processing machines. These include:

They can be used in such applications as:

SBPEMC and HWPPMC can also be used in the pharmaceutical sector, which also places emphasis on detectability.

Important for your quality management in the food industry:

Branching off cable at any point thanks to special profile

HWPPMC

Features

SBPEMC

Features