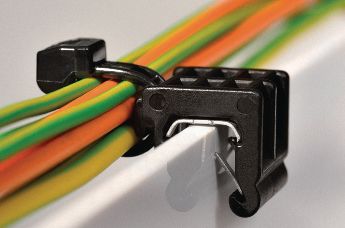

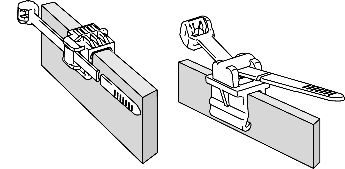

EdgeClip cable clips for edges are tiny cable tie mounts.

These special plastic components are held in place by built-in spring steel clamps.

The EdgeClip is a cable-fastening solution that enables the flexible routing of wires, cable harnesses, conduits and pipes in a variety of industrial applications, including the automotive sector.

Cable clips for edges allow you to securely fasten cables:

These cable clips can easily be attached to the edge by hand. No additional tools are required for installation.

Constructors and fitters often face the following challenges:

We have the right solution for you: The EdgeClip Mini – perfect for restricted spaces and narrow edges. The smallest EdgeClip model is specially tailored to the construction needs of our industrial customers.

The small dimensions of the EdgeClip Mini help constructors when there is limited space available for cable routing.

This mini version of our cable clip for edges keeps everything securely fastened, despite using 30% less material than the larger cable clips that we manufacture for thicker edges.

Thanks to its compact housing, the EdgeClip Mini is the only cable clip on the market that is suitable for securely fastening cables to very low square and double seam edges or narrow angled seam edges with thicknesses between 0.5 mm and 2.5 mm.

The EdgeClip plastic housing is made of high-impact-modified and heat-stabilised nylon, which is also known as polyamide PA66HIRHS – a material that is resistant to UV radiation, weather-induced chemical reactions and temperature fluctuations between -40°C and +105°C.

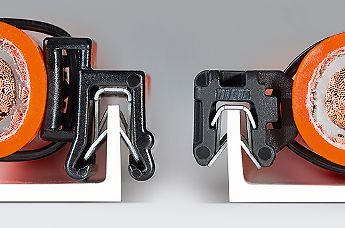

We have modified the design of the spring steel clamp inside the EdgeClip Mini to ensure that it has even more staying power than our industrial customers require.

The built-in, chrome-free, galvanised spring steel clamp digs itself firmly into softer materials. The barb effect is so strong that it isn’t even easy to prise away this tiny cable clip with pliers.

The barb effect of the spring steel clamps in all other HellermannTyton EdgeClip products have been designed for various surfaces and hardness levels.

Depending on requirements, we recommend that an engineer review the application of the EdgeClip model concerned.

Take a look at our video to see how you can remove an EdgeClip in a controlled manner.

If the base material of the edge (sheet metal or plastic) exhibits a hardness of less than 410 HV 10, the offset and interlocking claws of the EdgeClip Mini can withstand a pull-off force of 5 kg.

When compared with larger models, the design of the EdgeClip Mini facilitates the optimum positioning of the cable bundle on the edge, as well as the right position of the cable tie head in relation to the bundle for the application concerned.

There is no such thing as a universal cable clip for edges, as the applications in different industries can vary wildly. There are considerable variations in the edge dimensions and the materials used to make the edges.

We offer cable ties for three edge thicknesses

Our most frequent enquiries relate to the fastening of cables on sheet metal edges of between 0.7 mm and 0.9 mm – for which our EdgeClip Mini is the first choice.

Our EdgeClip Mini (EC0.5-2.5SP-SV) is also recommended for applications in which the edge measures just 6.0 mm in height.

The two-part EdgeClip EC5 cable tie is the best choice when it comes to fastening cables to edges with a minimum height of 9.0 mm.

HellermannTyton developed the EdgeClip to enable engineers to flexibly create fixed anchor points for cable ties on any part of component edges.

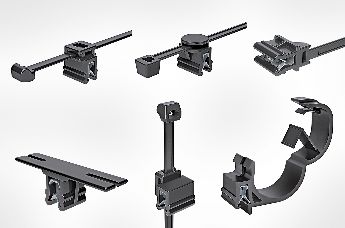

That’s why we offer a range of EdgeClips for cable tie insertion in different directions.

This makes it possible to route vertically and horizontally along edges or across or over edges.

The geometry of the edge concerned often indicates whether cables can be routed over, or alongside, the component edge.

You can choose between four different EdgeClip alignments:

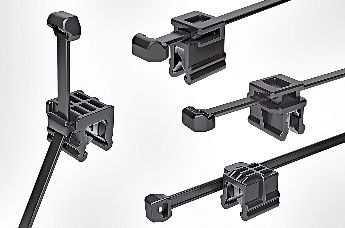

HellermannTyton developed the first cable clips for edges in 2001. These EdgeClips come pre-assembled with a cable tie.

Regardless of the size of the two-part EdgeClip, it is always a reliable anchor point on edges for bundling cables, pipes or conduits with cable ties.

Our customers usually order our cable clips for edges pre-assembled with a cable tie – ideally our T-Series cable ties with outside serration.

We now offer dozens of different two-part EdgeClip attachment sets.

We also produce single-part EdgeClip models: whether with the cable tie already attached to the clip housing, with a bundling clip or with closable mounts for pipes or conduits of different diameters.

EdgeClips are ideal for the secure fastening of wire harnesses in a host of OEM applications.

HellermannTyton developed the first EdgeClips for the automotive industry. In order to prevent the abrasion of fog lamp cables, the search began for a cable clip that enabled cable routing behind the bumper.

An existing edge constituted the ideal attachment point, with no costly series production modifications required.

The EdgeClips simply needed to be pre-mounted in the right places by the cable harness manufacturer.

EdgeClips are also installed in white goods. As they can be easily attached to edges by hand, they are predestined for piecework on production lines.

Completely at home in the elements, the EdgeClip also holds the cables on solar installations firmly in place. The two-part clip is resistant to UV radiation, temperature fluctuations and weather-induced chemical reactions.

It stops PV cables from sagging and being damaged, thus preventing short circuits.

In conjunction with software manufacturer CADENAS, HellermannTyton makes the specifications of selected EdgeClip products available in 3D electronic formats. Constructors can import the specifications of their desired items by downloading them into their CAD system free of charge in all standard CAD formats or by having them sent by email.

The PDF data sheet supplies information about precise product dimensions, material specifications, product characteristics and details of what is included in the scope of delivery.