Reduce. Reuse. Recycle ... Rethink

Making the material difference

Lowering carbon emissions through the choice of raw material and where it comes from is a challenge we willingly accept.

Sustainability covers various aspects, including material choices and manufacturing processes, but also product design.

At HellermannTyton, we offer solutions that are reusable, reduce waste, and use materials valuable in the circular economy.

For years, we've operated closed-loop systems that recycle waste into production and utilise residual heat. We're also switching to renewable energy wherever we can.

Helping you find the most sustainable material option

The next milestone in our journey to offer a carbon neutral product range is to reduce their product carbon footprint (PCF/cradle-to-gate) wherever we realistically can.

Talk to us to find the right solutions for your industry applications.

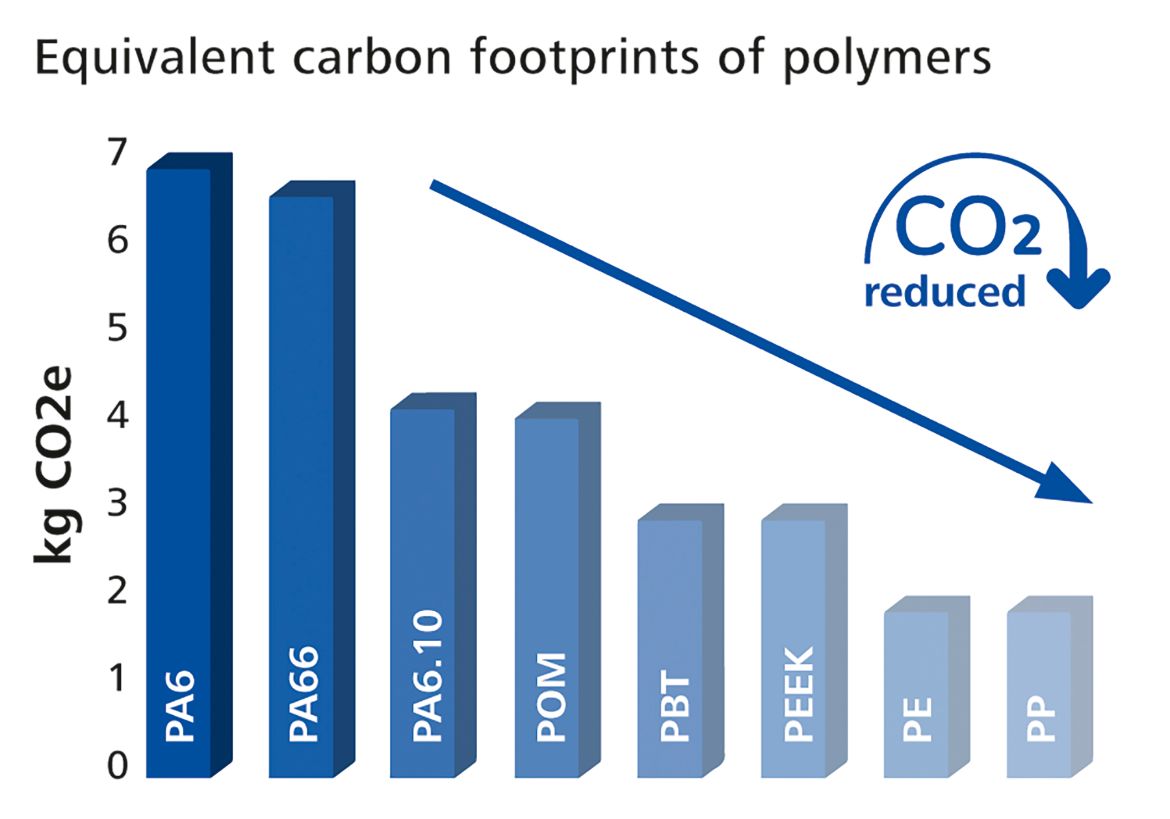

Different polymers, different carbon footprints

The amount of energy and the resulting emissions (CO2 equivalent) to extract and create plastic feedstocks vary depending on many factors.

That is why all the thermoplastics we buy and work with have different equivalent carbon footprints before we add more energy to transform them into our products.

Thermoplastic raw materials we commonly use include:

- Polyamide 6.6 (PA66 a.k.a. nylon)

- Polypropylene (PP)

- Polyethylene (PE)

- Polyethylene (PET)

- Polymethylene (POM a.k.a. acetal)

Data Source: Plastics Europe.

Did you know?

The amount of CO2 emitted per kg of polypropylene (PP) is approximately 33% of that emitted per kg of nylon (PA66).

Different polymers require varying processes and energy for production. Additives, such as those for strength, heat, or UV resistance, further alter the raw material and contribute to the net CO2 equivalent footprint.

Blending polymers like PP with PA creates lighter products, aiding fuel savings in vehicles. However, these blends are harder to recycle economically compared to pure thermoplastics like PP with conventional additives.

Bio-based materials from renewable sources

We already offer selected products made from bio-based feedstocks. These are plastics derived in whole or in part from renewable organic resources, rather than from finite fossil sources.

Examples include PA11 or PA6.10, which are derived from castor oil. PA11 is a very strong, lightweight and flexible material that is resistant to aging. That makes it especially suitable for long term outdoor applications like in solar energy parks.

Recycled content and circularity

Interest in circular business models for plastic resources is growing and we are increasingly helping customers to increase the amount of recycled material in their components.

Well-designed material reuse certainly produces fewer emissions than producing new material from fossil fuel sources.

→ Contact us here to find the right compound to meet your specifications while minimising emissions.

Contact Team Sustainability

Please use this form to send us your sustainability and governance enquiries. We will ensure that the appropriate person in our company provides you with the information you require as soon as possible. We look forward to hearing from you.

Contact us