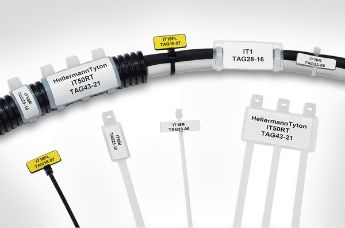

Whether cable and wire marking, solutions for industrial labelling in hazardous areas or security labelling with tamper evidence: HellermannTyton offers a comprehensive portfolio of cable labels and other marking solutions for a wide range of applications, from aerospace and rail industry to warehousing.

Our industrial identification solutions vary from simple pre-printed markers to inscribable adhesive labels and complete printing systems designed to process thousands of labels, heatshrink tubes or markers.

Most of our products have been developed in close cooperation with customers.

As a result, our portfolio now includes solutions that meet a wide variety of requirements: including security aspects, the need for traceability or compliance with legal requirements.

Self-laminating wrap-around cable labels consist of a printable or writable surface and a laminating function. This guarantees excellent protection of the printed text against moisture, dirt, deposits and mechanical abrasion. Due to their flexibility, most of these cable IDs are also suitable for flat ribbon cables, some of them for high temperature and outdoor requirements.

HellermannTyton offers a wide range of labels that meet most requirements:

Below you find some highlights from our cable label portfolio.

The TagPrint Pro labelling software contains templates for all HellermannTyton thermal transfer and laser printable products – from wire labels, markers to heatshrink tubing.

Simply select the built-in graphic or download your own and add data from the ERP system or standard programmes such as Excel.

Barcodes are created with a few clicks. The surface of all HellermannTyton labels has been specially prepared so that the printing performance with label printers is excellent at all times.

Laser-printable labels are a dependable solution for marking wires and cables in industrial environments. Their self-laminating design offers robust protection against humidity and abrasion, while rounded edges improve bonding strength for a secure hold.

Helatag1104 cable labels are ideal for users seeking standard, high-performance labels. Constructed from 25-micron material, these labels are both lightweight and durable, making them ideal for general labeling tasks.

For applications that demand longer and more durable labels, Helatag 1105 cable labels are the preferred option. With a 50-micron thickness, these labels provide added durability, making them well-suited to more demanding environments.

Our self-laminating cable labels Helatag 896 and Helatag 323 are suitable for thermal transfer printing, ensuring crisp, high-resolution markings that are both durable and professional. Also, Helatag 323 cable labels are especially designed for challening environments as they are resistant to high temperatures and UV radiation.

Available in different dimensions, materials and thicknesses, they consist of a printable area with a protective laminate layer. The transparent laminate layer protects the printed information from environmental factors such as humidity, dirt, abrasion, water, chemicals, UV and high-temperature resistance, ensuring stability under challenging conditions.

The self-laminating Helatag 1232 labels are ideal in harsh environments, e.g. for marking hydraulic pipes. They feature an extremely resistant protective over-laminate and can be printed comfortably with the HellermannTyton thermal transfer printer series.

The Helatag 1232 label series provides space for more information than just the serial number as they are much longer than standard self-laminating cable labels. The acrylate-based adhesive will not damage the hose.

The marking has good resistance to chemicals such as alcohol, petrol, solvents and hydraulic oil. Permanent cable identification is ensured by the flexible yet tear-resistant and impact-resistant polyester material.

Helasign 1402 cable labels offer durable and reliable solutions for wire and cable identification, making them ideal for low-volume maintenance tasks, whether for permanent or temporary markings. The self-laminating design protects against moisture, abrasion, and chemicals, ensuring reliable performance in demanding environments. These labels come in convenient, pocket-sized booklets complete with an applicator, allowing for quick, on-the-go use.

Key Features:

A fast and practical solution for low volume maintenance and repair work is the RiteOn self-laminating label dispenser for handwritten marking. To see how easy it really is, watch this video:

Every environment demands specific labeling solutions. In addition to self-laminating cable labels, we offer alternatives such as printable heat shrink markers, pre-printed cable markers, and cable tags.

Popular applications for HellermannTyton heat shrink markers and cable tags include:

HellermannTyton offers a range of heat shrink wire labels that deliver excellent print quality when paired with our thermal transfer printers. They are available in continuous format or pre-cut in a practical “ladder style” system. The following three options are specifically designed for reliability and safety in rail applications.

HellermannTyton 2:1 heat shrink markers are halogen-free, European rail-approved, feature low smoke propagation, density, and toxicity. They also allow for double-sided printing. TLFX heat shrink cable markers are supplied as continuous tubes and can be perforated or fully cut to predetermined lenghts.

TLFX DS heat shrink cable markers come in a ladder-style format. Similar to the TLFX marker, this version allows for double-sided printing thanks to its ladder-style format, making it easy to select individual markers as needed.

TLFD DS heat shrink cable markers are fluid-resistant and ideal for fire-sensitive applications. Pre-cut into a convenient ladder format, they offer enhanced resistance to organic fluids, fuels, lubricants, and solvents, while maintaining low smoke propagation, density, and toxicity

The cable markers TIPTAG PU and TAGPU are designed to withstand extreme conditions. Offering UV stability, resistance to weather and chemicals, and versatility to meet demanding requirements, these cable tags set the standard for cable and wire identification in harsh environments.

Equipped with fastening slots, they can be easily attached with cable ties, making them ideal for retrofit installations and adaptable to existing setups.

Made of a flexible polyurethane material, these cable tags combine durability with adaptability for challenging conditions. The TIPTAG PU cable tags are supplied pre-perforated in continuous reels whereas the TAGPU tags are supplied pre-cut in a ladder-style format, allowing for quick selection and use.

HellermannTyton offers a variety of pre-printed markers for cable and wire identification. These markers are available in yellow and in colours based on the international resistance color code. They feature characters 0–9, A–Z, and electrical symbols, printed using either laser or thermal transfer methods. The primary difference between the markers lies in their structure and how they are applied to cables. To simplify installation, accessories are available for all marker types.

WIC cable markers are designed for easy use on completed terminations or during maintenance. These vibration-resistant markers snap securely onto wires, preventing rotation and ensuring strong stability with perfectly aligned text. They come in a range of sizes (WIC0–WIC3) to accommodate cable diameters from 0.8 mm to 5.3 mm.

Ovalgrip and Helagrip cable markers are designed for slide-on application, allowing them to be applied directly to wires or cables before termination. Ovalgrip markers, featuring a straight cut, are suitable for cable diameters ranging from 1.7 mm to 6 mm. Helagrip markers, with a chevron cut to keep them together and maintain text alignment, are ideal for cable diameters from 1 mm to 9 mm.

IT-Series identification cable ties provide the unique ability to both identify and secure cable bundles in one step.

Identification plates, such as the IMP and IT Series, and Arrowtag range, are suitable for marking large cables, pipes, or flat surfaces, either before or after termination. These plates can be fixed using cable ties up to 4.8 mm wide.

Identification cable ties and plates can be manually identified with T82 indelible markers or by using our Helatag 892 labels.

Helafix HC and HCR cable carriers offer a versatile solution for marking cable looms, cables, pipes, transport systems, valves, sensors, and even inventory on machinery or other components. These transparent carriers are designed to accommodate HFX labels, offering options for both temporary and permanent marking.

Key features include:

There are a variety of cable and wire marking solutions suitable for the permanent marking of components and pre-assembled units in the electrical industry as well as for plant machinery marking.

These industrial identification solutions can also be used for construction and commissioning as well as for repair and extension of switch cabinets and control systems.

Have a look at some selected product highlights which are often used in the field of industrial labelling.

Thermal transfer panel labels such as Helatag 1220 (white) and Helatag 1221 (silver), are a cost effective alternative to engraved plates. Ideal for industrial control panels, switchgears and general identification equipment, they provide a reliable identification solution without the need for screws or bolts.

These durable, self-adhesive labels offer:

The handwritten HELASIGN 270 labels made of yellow fabric are designed for the quick identification of components, switchgear and other on site equipment.

Thanks to the synthetic rubber adhesive, the label can be easily removed or repositioned if necessary – without leaving any adhesive residue.

The labels are also suitable for tricky surfaces and are available with or without a black frame. They are supplied in handy pocket-sized booklets and can be marked with T82 marker pens.

Efficient type and asset identification is critical in industrial environments. The Helatag 1204 type label , designed for thermal transfer printing, is built for tough industrial applications. Durable, versatile, and featuring a silver-matt finish, it is an excellent alternative to traditional aluminum plates. These labels are scratch-resistant, adhere well to critical surfaces, and perform reliably in high-temperature environments.

For laser printing, the Helatag 1101 (white) and Helatag 1102 (yellow) type labels, offer simplicity and flexibility. These labels are perfect for marking control cabinets and components, as they are ideal in applications requiring clarity, such as barcode printing or high-definition graphics.

Coloured labels Helatag 1213 are essential for efficient warehouse and pipe labelling, offering a practical solution to identify storage systems with both barcode and location information. They are also versatile, suitable for marking parts, components, samples, and blocked goods in quality assurance, ensuring clear and durable identification.

Key benefits are:

• Versatility: Suitable for pipes, warehouse shelves, and general storage needs

• Easy Handling: Supplied on a continuous reel, labels can be cut manually or using automated printer cutters

• Adaptability: Designed for use on rough surfaces

• Durability: Offers good resistance in outdoor environments, ensuring reliable performance over time

HellermannTyton offers a range of materials that enable customers to quickly identify whether assets have been tampered with. For general inventory management, Helatag 1203 labels provide similar tamper-evident features for secure asset marking. These versatile labels can be printed with text, graphics, or barcodes, delivering flexible solutions for various identification requirements. Perfect for marking equipment and inventory, they ensure clear, reliable, and unambiguous asset identification.

Specifically designed for robust identification on trucks and trailers and in the automotive market, the Helatag 1251 tamper-evident labels provide a highly visible and durable marking and are an effective alternative to conventional aluminium plates. These labels leave a clear indication if removed, providing strong tamper evidence for enhanced security.

A transparent protective laminate ensures resistance to dirt and abrasion, making them highly durable for both indoor and outdoor applications. With a strong adhesive and sturdy construction, these labels stay firmly in place, offering reliable protection for your identification needs.

HellermannTyton MBML metal cable markers, made of 316L stainless steel, are versatile and find applications across various industries due to their durability, corrosion resistance, and ability to withstand harsh environments, ensuring efficient operations, safety, and proper maintenance. Here are some examples of applications for SS316L cable markers in different industries:

Product features:

316L is a low carbon variety of the widely used 316 stainless steel. “SS316L” stands for “low carbon”, which indicates that the composition of this stainless steel has a lower carbon concentration, meaning there is additional resistance to corrosion. Therefore, SS316L marine grade is typically used in harsher and more demanding environments than standard 316 stainless steel.

316L steel properties:

| Material | High temperatures | UV resistance | Salt corrosion | Galvanic corrosion | Chemical resistamce | Flammability |

| SS316L | excellent | excellent | excellent | limited | excellent | none |

The M-BOSS Compact stainless steel embossing system has been designed for easy printing of our MBML series metal cable markers, providing clear and durable identification, crucial for hazardous areas. The key features of this metal marker engraving equipment are:

First of all, what requirements do you have for a cable label or cable marker? Or in other words: What requirements must be fullfilled? Basic aspects here are, for example, whether the material is exposed to temperatures above or below 90 degrees Celsius, whether it should be tamper-proof or UV-resistant.

The HellermannTyton label and marker selection guide will help you. See for yourself and find the right product for your application!

The first step is to determine which cable diameter you need for your application. Or when it comes to labelling or marking cables: what cable diameter am I dealing with?

Once this is known, the HellermannTyton size selection guide will help you find the right product for your application. Try it now!

A special feature is that most HellermannTyton protective laminate labels have rounded corners. This results in higher final adhesion of the protective laminate and counteracts unwanted removal of the wire label, especially with small diameter cables and in heavy applications.

What else to consider and how to calculate the right size for your protective laminate? Check out our instructions for using labels with protective laminate!

HellermannTyton offers various systems that can print different types of material/labels. If you would like to know which product is the right one for your cable label or cable marker, this table gives you a good overview. See for yourself!

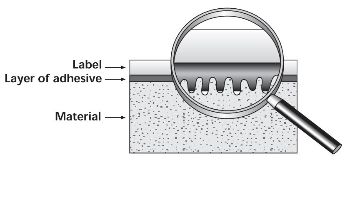

Basically, a distinction is made between the following two states: the initial bond, which occurs immediately after the label and surface have been joined, and the final bond, which represents the permanent bonding state between the label and surface after the adhesive has been applied, pressed on and cured. Factors influencing optimum adhesion include the quality of the surface material and the properties of the adhesive.

What else needs to be considered? Learn more in our brochure bonding properties of labels!

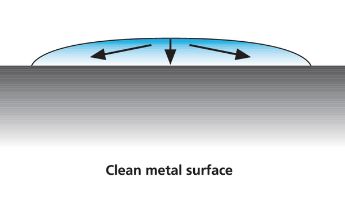

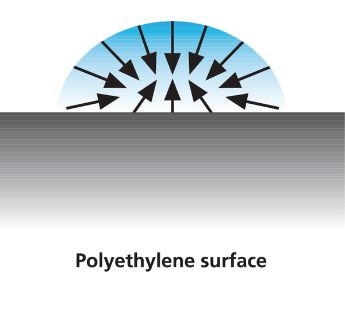

If a surface to be marked is wet out with an adhesive, the surface energy is a decisive factor for the maximum achievable adhesive strength of the adhesive – in addition to the adhesive formulation and the surface quality (material, roughness, moisture, etc.).

Flat drops:

Rounded drops:

What exactly is it all about? Learn more here: in our brochure effect of surface energy on bonding properties!