Cable management is a critical yet often challenging in solar installations as they involve numerous cables that connect photovoltaic panels, inverters, and other components, all of which must be organised to ensure efficient energy transmission and safety. The complexity of solar cable management arises from the need to protect cables from environmental factors, such as UV radiation and extreme temperatures, while also accommodating the large scale and varying layouts of solar arrays.

Effective solar farm cable management helps prevent electrical faults, minimises downtime, and extends the lifespan of the system, ultimately contributing to the overall efficiency and reliability of solar energy production. Overall, well-executed cable management for PV panel installation can significantly enhance cost-effectiveness. Balancing these demands makes solar farm cable management both a crucial and intricate task in optimising solar plant performance.

HellermannTyton offers solutions that help prevent photovoltaic panel downtimes. These solutions are designed to ensure long-term reliability, with some specifically developed for the solar sector.

This checklist is designed to assist installers in the correct application of cable ties, clips, and clamps to solar modules.

Check it out now and learn how to find the right solution for your specific solar panel installation needs.

1. Avoid “Cable Curves”: Never tie cables in an oval shape. Oval lashings are one of the most common causes of premature failure. This type of lashing can break over time due to movement caused by thermal expansion and wind. Make sure cables run in straight lines rather than ovals.

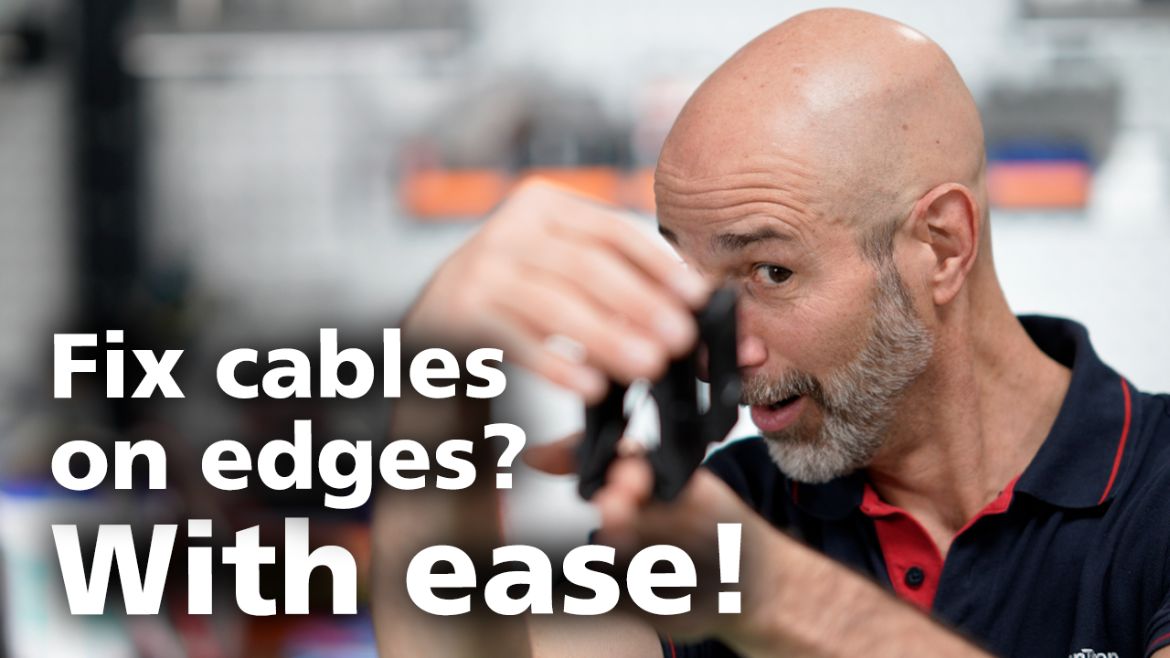

2. Never tie cables near a metal edge without a suitable product: There is a high risk of damaging the cable sheath, which can cause short circuits and, in the worst-case scenario, a fire.

3. Use appropriate fastening clips for perforations: Use LOC series clips for mounting holes on the solar module. The clip with fir tree and LOC series clips are most suitable for photovoltaic systems. These clips not only secure cables but also enable cable tying—all in one product.

4. Use solar cable clips to avoid drilling panels: Edge clips are some of the most flexible and durable solar cable management solutions on the market. UV-stabilised and made of stainless steel, MSC2 edge clip models allow you to hold one or more cables without drilling. This ensures that cable insulation remains intact and is not exposed to the elements.

5. Take special care with cables in floating photovoltaic systems: For underwater applications or cabling exposed to moisture, ensure that cables and connectors are properly protected and managed to prevent damage.

6. Use mounting points appropriate for the number of solar modules: Cascade effects can result from incorrect sizing of the mounting points. If mounting points are not sized correctly and a fault occurs in one of the fixing elements, a cascade effect may occur, leading to energy loss and potential damage to the system.

7. Clamps for solar applications must meet a wide variety of requirements: It is crucial that clamps are made of materials resistant to UV light and can handle movements, such as those caused by solar trackers. Additionally, clamps in solar applications must withstand various temperature fluctuations.

8. Avoid exposed, sharp, or pointed edges: Sharp or pointed edges can damage cables, potentially causing short circuits.

9. Always ensure proper cable routing: Poor cable management can lead to issues such as excessive strain on junction boxes, resulting in frequent maintenance.

10. Always refer to this checklist when installing cables on photovoltaic plants: Following this checklist is the best way to ensure the safety and efficiency of your photovoltaic solar installation.

Discover in our webinar on PV lifetime guidance (get access after a free registration) how to prevent poor cable practices that reduce the lifespan of solar installations. Georg Neureiter, an expert in solar farm cable management, discusses key factors affecting performance, such as environmental aging and grounding faults, and provide solutions to enhance efficiency over a 25-year lifespan.

Efficient solar farm cable management requires reliance on the right materials and the perfect product choosing appropriate materials and products for your specific application. Plastic products are generally not suitable for the solar industry and are often considered a lower-quality alternative to metal. But as with all products, quality depends on the material and the manufacturer, as not all plastic wire and cable management products are designed and manufactured the same way. Don’t let the perception of supposedly inferior plastic products keep you from looking for and using a stronger, well-made, longer-lasting plastic cable tie.

Webinar: Rooftop and fixed-tilt applications

Learn in our webinar on rooftop and fixed-tilt cable solutions (get access after a free registration) how to maximise the efficiency and longevity of your rooftop and fixed-tilt solar installations through proper cable management. Our solar expert Georg Neureiter will provide in-depth guidance on a range of solutions, from cable ties and edge clips to ratchet P-clamps and identification tags, all tailored to specific applications and environmental conditions.

Join us to discover the best practices for selecting the right products for solar farm cable management and boosting your solar system’s performance.

HellermannTyton offers various fixing elements that can be applied to solar panels without screws. Edge clips are commonly used for installations in solar farm cable management because they provide a secure and efficient way to manage and organise cables without the need for drilling holes or using adhesives, which can compromise the integrity of the solar panels or mounting structures. Besides avoiding damage to support

structures, the easy installation saves time and is cost-effective. Solar clips and cable ties equipped with UV stabilisers are available in a variety of materials, sizes, and tensile strengths to suit any solar application.

A particularly efficient solution for solar installations is the C-clip with a fir tree mount. Ideal for panels with pre-drilled holes, this clip allows for quick and easy hand installation, eliminating the need for tools. Constructed from PA66HIRHSUV material, the clip is engineered to endure extreme conditions, offering flexibility, heat resistance, and UV stability. This ensures long-lasting performance in demanding environments.

Solar installations often involve placing cables in outdoor environments where exposure to weather elements like wind and moisture is a concern. Solar cable clips attach directly to the metal frames or edges of solar panels, ensuring that the cables remain secure and protected from physical damage, environmental exposure, and potential interference.

Our solar solutions, made from UV-resistant polyamide 11, last five to seven times longer than a standard solar clamp with a UV rating. Parts made from UV-stabilised plastic, along with other stabilisers, can significantly increase the lifespan of these products. In fact, some plastic compounds can last 15 to 25 years. Choosing engineering plastics designed to perform in solar components will certainly pay off. Additionally, UV-stabilised cable ties remain functional and reliable under intense sunlight, reducing maintenance costs and ensuring greater safety by preventing degradation from prolonged exposure to UV rays.

Check out our solutions for a permanent, legible, and UV-resistant cable marking. Are your identification tags faded by the sun? Covered in dust and dirt? Our ID products like cable labels, cable tags, and cable markers offer a permanent, legible, and UV-resistant marking. They remain readable for years, even under intense sunlight or when they are faded, saving you time and money on frequent replacements. They also withstand rain, snow, and extreme heat, so you do not have to worry about damaged or unreadable labels. Even when they are covered by dust or dirt, they can be read, minimizing errors and simplifying maintenance tasks.

The CPK hybrid cable tie gun is a fast and flexible battery and mains-powered cable bundling tool designed for use in solar panel installations. It features five tension settings and three quality settings, and can be powered by a fast-charging 18-volt battery from CAS or

from grid power. With five tension settings, you can tailor the tension precisely to your needs, ensuring secure bundling without overtightening or damaging the solar panel wiring.

This cable tie gun enables you to bundle cables quickly, with maximum cycle times of just 0.65 seconds. Not only does this reduce the time and effort spent on solar system installations, but it also decreases waste by collecting the cut-offs as you work. Enjoy extended operational time with the reliable battery power, minimizing downtime and ensuring consistent performance in demanding solar environments. Plus, with its max binding time, you can complete tasks faster, reducing overall labor costs and speeding up solar panel project timelines.

Sustainability is an integral part of energy generation from renewable resources. And this is also true for the cable management solutions you use on photovoltaic installations. Are you looking for ways to make your solar farm cable management more sustainable? Watch the video and don’t hesitate to contact us directly.

Order free samples, try them out on-site and discover how parts especially designed for the solar industry can improve the efficiency of your PV installation and the reliability of your solar plant operation.

Solar farm cable management solutions from HellermannTyton are as versatile as the different regions and areas of application themselves. When searching for the perfect product, personal consultation is the best way to go. The experts at HellermannTyton are happy to help you find the right product for your solar cable management and drastically reduce your overall costs in the long run as a result.

Our mission is to help you advance your solar project, wherever it is located around the globe.

Join expert Georg Neureiter in our webinar on optimizing LCOE with efficient solar cable management (get access after a free registration) as he explores how proper cable management can reduce the levelized cost of electricity (LCOE) in solar installations. This webinar breaks down LCOE components - OPEX, CAPEX, and yield - and demonstrates how HellermannTyton solutions contribute to optimized cost per kWh. Expect clear overviews, product examples, and a detailed sunburst diagram to help you make informed decisions for your solar installations.

Setting a low CAPEX for solar farm cable management might seem cost-effective, but it can lead to significant maintenance expenses over time. Cutting corners on cable solutions results in damage, failure, and costly repairs.

Explore in our webinar on choosing the right materials for solar PV cable ties (get access after a free registration) how advanced materials can improve the cost-efficiency of solar farm cable management. Learn about the impact of UV irradiation on various plastics, compare material characteristics and costs, and discover test results from Fraunhofer ISE on cable ties. Gain valuable insights to enhance the durability and performance of your solar installation.

Choosing the right material is an essential part of your solar cable management strategy and ensures the long-term efficiency of your photovoltaic (PV) installation.

Our white paper provides expert insights into the advantages of plastic and metal in solar cable management, comparing key factors such as UV resistance, mechanical strength, corrosion protection, and cost-effectiveness. It explores how environmental conditions impact material performance and offers decision strategies to ensure durability and reliability.

Gain a deeper understanding of which materials best suit your specific application and optimize the efficiency of your solar installation.

In order to better understand the effects of UV radiation on different kinds of plastic used in cable ties, HellermannTyton commissioned the Fraunhofer Institute (ISE) to conduct a series of tests under natural and accelerated conditions in Central Germany and in the Negev Desert in Israel.

Inefficiencies due to unsuitable cable management systems can lead to increased maintenance and downtime, jeopardize overall installation efficiency, and may endanger personnel. The outcome will be higher cost both financially and in terms of safety.

The white paper explains how the tests were conducted and presents the results for different types of plastic ties, underscoring the need for operators and installers to carefully consider materials and conditions when choosing retainers.

During a field trip, Georg Neureiter – our expert in cable management for photovoltaic installations - meets with industry experts from Hallertauer Handelshaus GmbH, specialists in photovoltaic systems. Together, they visit an agrivoltaic solar plant where sheep graze safely beneath the solar panels. The term 'safely' refers to how cables are securely held in place to prevent dangerous dangling that could harm the sheep or damage the installation

Discover in our webinar cable management solutions for horizontal tracker and agrivoltaic solar installations (get access after a free registration). Learn how to minimize damage, improve safety, and enhance efficiency by choosing the right retainers for conditions like movement and humidity. Join our expert for detailed insights to make informed decisions for your solar farm cable management.

Feeding cable ties through the mounting holes of solar modules is generally advised against because it can compromise the module's structural integrity and create stress concentrations. This practice may also lead to moisture and debris buildup, causing corrosion and affecting performance. Additionally, cable ties can interfere with temperature-induced expansion, pose safety hazards if they degrade, and negatively impact the installation's appearance.

For optimal solar module installation, use cable management clips or channels specifically designed for solar systems to organize cables without affecting the module. Always follow the manufacturer's installation guidelines and use compatible mounting hardware to ensure secure attachment and proper cable routing. Route cables externally from mounting points, secure them with appropriate solar cable clips, and regularly inspect the setup to prevent damage and maintain performance.

To avoid contact corrosion in edge mounting for solar installations, use corrosion-resistant materials like stainless steel or aluminum alloys with protective coatings. Apply anti-corrosion coatings and ensure all connections are tight and sealed. Design the system for effective drainage and avoid using dissimilar metals together. Regularly inspect and maintain the system to address any signs of corrosion early.

Good cable management in the solar industry is crucial for ensuring system safety and reliability. It helps prevent physical damage to cables, reduces the risk of electrical faults, and facilitates easier maintenance and troubleshooting. Proper cable routing also minimises exposure to environmental factors like UV radiation and moisture, which can degrade cables over time. Overall, proper solar cable management leads to lower maintenance costs in the long run which is important as operators of photovoltaic installations face enormous cost pressures to compete with fossil fuel energy generation.