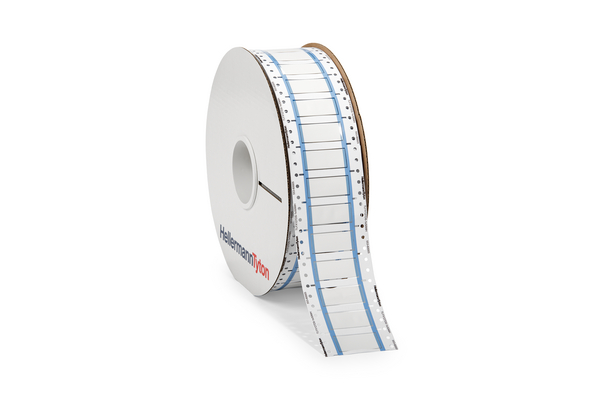

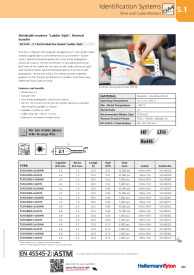

Heat shrink marker, thermal transfer print, ladder-style, 38.1mm/19.1mm, W=50.0mm, white, 500pcs.

Nr. articol 553-60008

| TLFX381DS-1x50WH-PO-X-WH

|

Copied

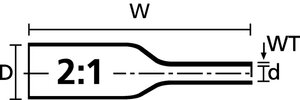

- Shrink ratio 2:1

- Halogen Free

- Low smoke propagation, density and toxicity

- 50 mm, 25 mm and 16 mm pre-cut marker options as standard

- Available in yellow or white

- Other lengths and colours available on request

- Cable range 38.1 mm to 1.2 mm

- Delivery in convenient storage boxes

Solicitați acum oferta dumneavoastră individuală

Solicitați oferta

Mai multe produse în acest grup de produse:

| Application | TLFX DS is a halogen free European rail approved 2:1 heat shrink marker material supplied pre-cut and formatted into a convenient "ladder" system. Special material properties show low smoke propagation, density and toxicity. This pre-cut format not only allows printing on both sides of the marker but the user can also easily choose and pick each required marker. Special material properties show low smoke propagation, density and toxicity. The tubing has been especially prepared so that the print performance is excellent at all times using HellermannTyton's printer range. |

| Behaviour at low Temperature test method | ASTM D2671 |

| Colour | White (WH) |

| Fixation Method | Suspend |

| Heat Aging Test | 168h/150°C |

| Heat Aging test method | ASTM D638 |

| Heat Shock Test | 4h/175° |

| Material | Polyolefin, cross-linked (PO-X) |

| PART DESCRIPTION | TLFX381DS-1x50WH-PO-X-WH |

| Pack Cont. | 500pcs. |

| Package Content packed in | carton |

| Printable | Yes |

| Product Family | TLFX DS – 2:1 Rail Limited Fire Hazard "Ladder Style" |

| Product Group | Shrinkable markers "Ladder Style", thermal transfer |

| Short Description | Shrinkable markers ladder style, thermal transfer, 2:1 (38.1 mm/19.0 mm) white 50 mm |

| Shrink Ratio | 2:1 |

| Type | TLFX381DS-1x50WH |

| Variant | Roller form |

| With inner glue (Yes/No) | No |

| With label space | No |

| For AWG | 400+ |

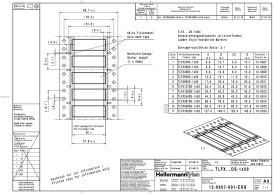

| H printable | 76.2mm |

| Height (H) | 76.2mm |

| Longitudinal Change After Shrinkage | -5% max. |

| Longitudinal Change After Shrinkage test method | UL 224 |

| Max. Wire Size (in²) | 1.4" |

| Outside ⌀ max (OD max.) | 38.1mm |

| Outside ⌀ max. | 1.5" |

| Print Method | thermal transfer print |

| Print Method (Alternative) | laser beam print |

| Recov. ⌀ d max. | 0.75" |

| Recov. ⌀ d max. | 19.1mm |

| Supplied ⌀ D min. | 1.5" |

| Supplied ⌀ D min. | 38.1mm |

| Thickness (T) | .29mm |

| VR | 4.0" |

| VR | 101.6mm |

| Wall (WT) | 0.975mm |

| Wall (WT) | 0.038" |

| Weight/Unit | 0.006kg |

| Width (W) | 50.0mm |

| Width of LIner (WL) | 3.50" |

| Width of Liner (WL) | 88.9mm |

| Width printable | 50.80mm |

| Wire Size Range (in²) | .75 - 1.4in² |

| Abrasion Resistance | High |

| CE Certification | No |

| CSA Certified | No |

| Dielectric Strength | 20kV/mm |

| Dielectric Strength test method | ASTM D2671 |

| ELV compliant (Article 4 - 2) | YES |

| Elongation at break | 200 % |

| Elongation at break test method | ASTM D2671 |

| Flammability | UL 224 |

| Halogen-free | Yes |

| Hazardous Goods | No |

| Limited Fire Hazard | Yes |

| Min. Shrink Temperature - °C | +100 °C |

| Operating Temperature | -55 °C to +105 °C |

| Oxygen index | 34.9% |

| Oxygen index test method | ISO 4589 |

| ROHS compliant | Yes |

| Recommended Ribbon Type | TTDTHOUT |

| Reel Variant | ladder-style |

| Shelf Life | 24 months |

| Smoke density | 44Ds (max) |

| Smoke density test method | ISO 5659-2 |

| Specifications | ASTM 1354, ASTM E 162, ASTM E 662, EN 45545-2, NFPA 130 compliant |

| Specifications |

|

| Tensile Strength | 11MPa |

| Test Method Tensile Strength | ASTM D2671 |

| Toxicity index | 0.03CITg |

| Toxicity index test method | EN 17084 |

| US Gov. Designation | MIL-STD-202J, SAE AS5942 3.4.1 |

| UV-Stabilised | No |

| Volume Resistance | 10¹⁴ Ω cm |

| Volume Resistance test method | ASTM D257 |

| Water Absorption | 0.15% |

| Country of Origin | DK |

| Customs Number | 39173200 |

| GTIN-13 / EAN | 4031026321509 |

| Markers per row | 1 |

| Packaging 1 - Height (m) | 0.12m |

| Packaging 1 - Length (m) | 0.318m |

| Packaging 1 - Qty | 500 |

| Packaging 1 - Type | bag |

| Packaging 1 - Volume (m³) | 0.01270728m³ |

| Packaging 1 - Weight (kg) | 3.200001kg |

| Packaging 1 - Width (m) | 0.333m |

| Storage conditions | 50% relative humidity., The storage in the original packaging is recommended., Please avoid warehousing under impacts such as high humidity, heat and coldness. |

Argentina

Argentina Australia

Australia Brazil

Brazil Bulgaria

Bulgaria China

China Czech Republic

Czech Republic Denmark

Denmark Finland

Finland France

France Germany

Germany Hungary

Hungary India

India Italy

Italy Netherlands

Netherlands North America

North America Norway

Norway Poland

Poland Portugal

Portugal Romania

Romania Russia

Russia Singapore

Singapore Slovenia

Slovenia South Africa

South Africa South Korea

South Korea Spain

Spain Sweden

Sweden Switzerland

Switzerland Türkiye

Türkiye United Arab Emirates

United Arab Emirates United Kingdom

United Kingdom

Descărcare

Descărcare

TT4030

556-04037

TT4030

556-04037 TT431

556-00400

TT431

556-00400 TT4030DS

556-04061

TT4030DS

556-04061 Sample Pack ID shrinkable markers, thermal transfer

905-50003

Sample Pack ID shrinkable markers, thermal transfer

905-50003 H6100

391-00110

H6100

391-00110 TTDTHOUT 60MM

556-00140

TTDTHOUT 60MM

556-00140 TLFX254DS-1x50WH-PO-X-WH

553-60007

TLFX254DS-1x50WH-PO-X-WH

553-60007 TLFX254DS-1x50YE-PO-X-YE

553-60017

TLFX254DS-1x50YE-PO-X-YE

553-60017