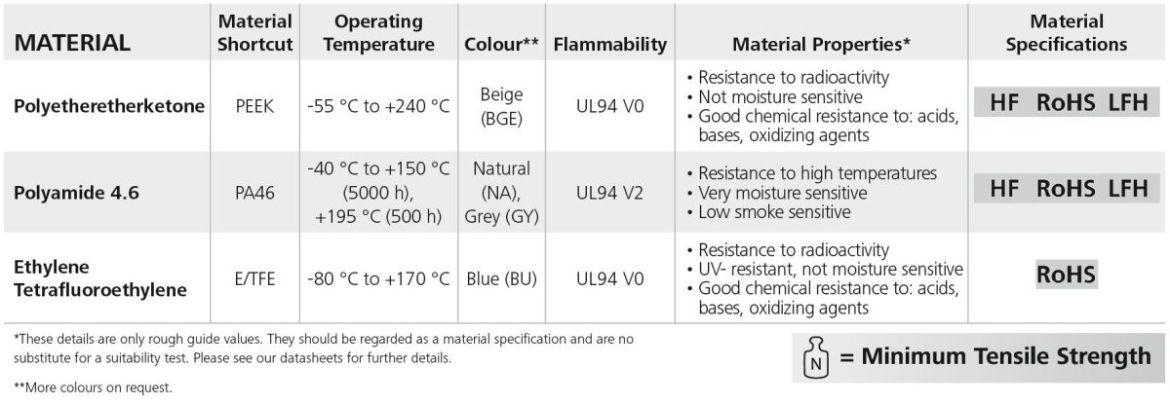

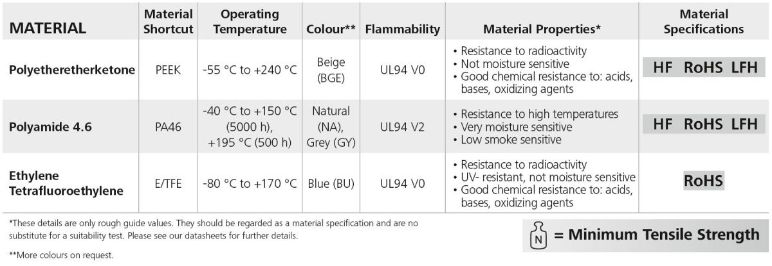

High temperature is a key issue from the automotive industry to aerospace, rail, ship building and chemical industry, engineers face challenges posed by high temperature scenarios time and again. We develop customised products such as heat resistant cable ties made of plastics, high temperature insulation products or heat resistant sleeving to meet your individual demands. We replace metal with plastics such as PA46, PEEK and E/TFE (Tefzel®) – even in applications involving a high operating temperature – without compromising on quality and performance.

Our customers profit from many advantages offered by heat resistant plastics, such as

HellermannTyton's core competence includes development and manufacture of plastic injection moulded parts, both in the single as well as in the more-component technology. Our long-standing expertise in the production of high-quality plastic components for cable management solutions is bundled in our Technology Centre.

Would you like to discuss the demands and solutions of high temperature applications?

Your suggestions are our inspiration for a new product to meet the demands of your application.

Get in touch with us!

Following we would like to focus on HellermannTyton’s competence in injection-moulded cable management solutions made from high-performance, high-end thermoplastic such as PEEK, PA46 and E/TFE – products designed to withstand high or fluctuating temperature conditions.

By the way, we also have competence in the field of solar – with a lot of expert knowledge and innovative product solutions, some of them specially developed for the solar sector. Learn more here:

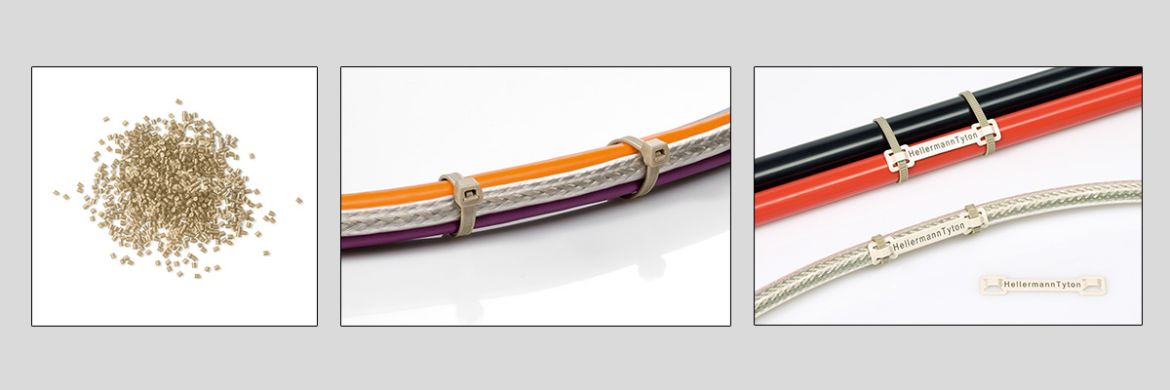

The heat resistant material PEEK is considered to be one of the highest-performing thermoplastics on the market.

HellermannTyton`s products manufactured from PEEK have been designed for use in hazardous environments and are suitable for applications where temperatures can reach +240 °C (continuous operating temperature).

As well as having excellent radiation resistance properties, PEEK is highly resistant to chemicals. PEEK products are suitable for the use in various applications and industrial sectors.

We replace metal components with solutions made of plastic. Due to its combined properties, PEEK can be used instead of metal components to offer unique weight advantages in your applications.

Advantages of the heat resistant material PEEK:

Have a look at our PEEK product selection, such as

- PEEK Ties, inside and outside serrated

- 1 and 2-piece fixing ties with arrowhead, with disc

- Screw fixing mounts

- Identification plates for marking cable bundles

More variants and dimensions are available on request. Please contact us for more information.

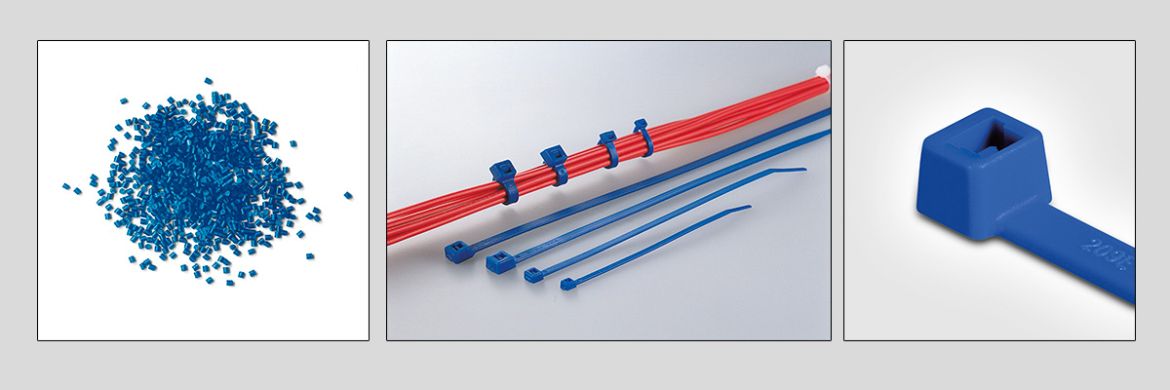

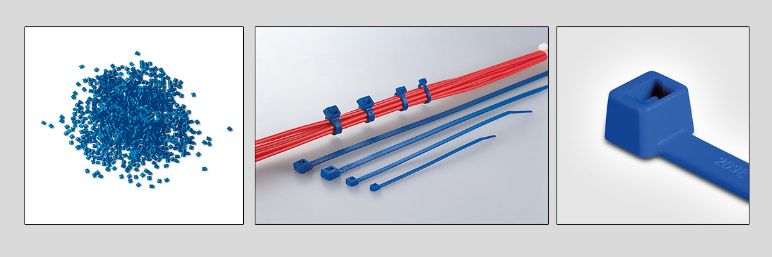

The heat resistant material Polyamide 4.6 is suitable for temperature applications up to +150° C. Besides its resistance to high temperatures, PA46 is also highly rigid. PA46 products also offer good fire safety properties at high temperatures and excellent resistance to chemicals.

Advantages of the heat resistant material PA46:

• For temperatures ranging from -40 °C to +150 °C

• High-quality plastic that can be recycled easily

• High rigidity, even at high temperatures

• High operating temperature range up to +150 °C (5,000 hours)

• High dimensional stability, even under the effect of heat

• Very good fire safety properties

• Excellent resistance to chemicals

Have a look at our PA46 product selection:

Heat resistant cable ties:

- T-Series inside serrated cable ties

- OS-Series outside serrated cable ties

- V-Series cable ties with 90° angled head, outside serrated

- DH-Series cable ties with 2 heads (create an inside and outside serrated loop) for parallel routing

(of two bundles with only one cable tie)

- KR-Series cable ties locked by glass fibre pin, for use as a method of securing bellows on steering racks, water hoses and vacuum lines

Heat resistant cable ties with fixing elements:

- Cable ties for Autotool 2000 Series, automatic bundling up to Ø 20 mm

- 1-piece fixing ties with arrowhead, with wings, for use in many different industries, including automotive, aerospace and panel building

- 1- and 2-piece fixing ties with fir tree, with disc

- 1-piece fixing ties for weld studs (hardpush), releasable

- 1-piece fixing ties for Weld, moveable

- 2-piece fixing ties for Weld Studs

- 2-piece fixing ties with coupler for parallel separation

- 1- and 2-piece fixing ties with pipe clip

- Cable set clip for cable diameter 5 and 6 mm

- 2-piece fixing ties for edges, 1.0 - 3.0 mm, side fixing

- 2-piece fixing ties for heavy duty applications, for screws

Heat resistant fixing elements:

- Bundling clips with arrowhead for distance routing

- Bundling clips for edges, 1,0 - 3,0 mm

- Blind plugs

More variants and dimensions are available on request. Please contact us for more information.

E/TFE products are ideal for use in aggressive chemical environments at temperatures up to +170 °C. This highly resistant thermoplastic meets UL94-VO fire protection requirements and generates very little smoke density.

Advantages of the heat resistant material E/TFE:

• For temperatures ranging from -80 °C to +170 °C

• Continuous use at +170 °C

• Very good resistance to acids, bases and oxidizing agents

• Not hygroscopic, i. e. no water absorption

• UV-stable

• Very good resistance to chemicals

• Very good resistance to weathering

• Good resistance to radiation

• Good impact strength

One example is the inside serrated cable tie made of E/TFE from our T-Series, have a look here.

More variants and dimensions are available on request. Please contact us for more information.

In addition to the products made of PEEK, PA 46 and E/TFE we offer system solutions made of various materials, which are also suitable for high temperature applications. We have compiled the most suitable products from the range:

• Heat shrinkable tubing with and without adhesive liner

• Flexible PTFE protective tubing

• PTFE protective tubing and spiral binding

• PTFE edge protection grommets

• NOMEX expandable braided and open woven sleeves

• PVDFX identification tags for cable bundle for thermal transfer printing

• PVDFX heat shrinkable wire identification for thermal transfer printing

• Automatic cable tying systems and application tooling for cable ties

We are even able to produce protective sleeves and identification solutions made of these special materials, which have the same excellent properties and perform just as well in high temperatures as our standard products. For example, our PVDFX identification tags can be printed with a common thermal transfer printer.

Have a look at our product selection:

High temperature insulation products:

• Elastomer SE28

• PVDF TK20

• FPMX Viton E

• PTFE-TFE2

• PTFE-TFE4

Heat resistant sleevings and edge protection products:

• PTFE CTT

• PTFE SBPTFE

• PTFE Flexiform Grommet

• NOMEX HEGMAN

• NOMEX HEGMANWO

High temperature identification products:

• PVDFX TAGHT

• PVDFX THTT DS 2:1

• PVDFX THTT

Application Tools:

• EVO7

• KR Tool

• AT2000CPK

• M3PNSP2

• MK7P

• MK9P

• MK3SP

For over 80 years we have been applying our experience and innovative drive for the benefit of our customers in markets throughout the world.

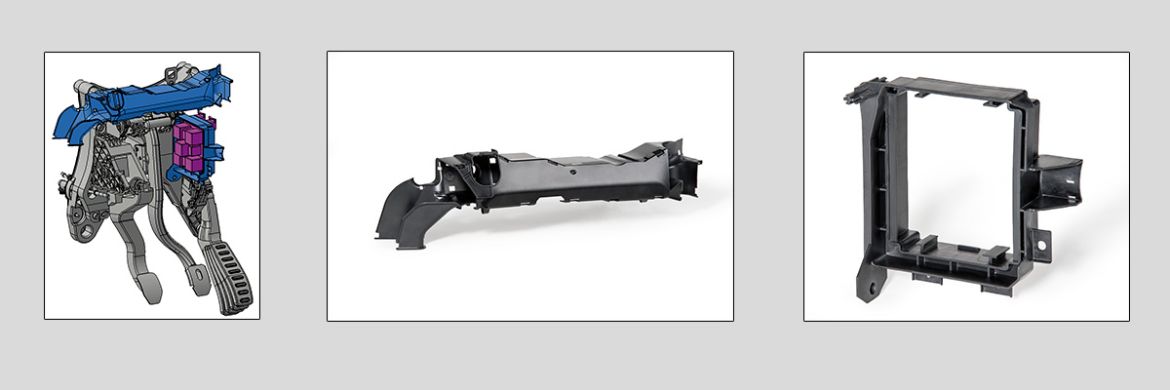

We develop products tailored to your specifications. To do this we rely on state-of-the-art CAD and rapid prototyping systems. Through the use of advanced development tools, our experienced designers guarantee a high level of quality in all our products.

The result: innovative solutions and the chance for you to profit from these advantages.

Save development time

Our product developers work simultaneously with your engineers while we develop the solution. This shortens the development phase, even for parts whose dimensions have not yet been fully finalised.

Reduce weight

Replace metal by plastic without compromising on quality and performance. HellermannTyton injection-moulded parts offer complete freedom in geometric design, allowing easier integration of other functional elements. They are also corrosion-resistant.

Reduce component diversity

Using our targeted cable-set analyses, we are able to offer you cost-effective alternatives, demonstrate the application of preferred parts and show you how components can be optimised.

Choose the right material

Our many years’ experience in product development will help you in choosing the right materials. If a suitable material for your application does not already exist, we will work closely with you and our raw materials suppliers to develop one. We are your reliable partner throughout the entire development process – from initial contact to serial production.

Our expertise

‘Resident engineering’ is the most profitable form of knowledge transfer. For large-scale or special projects, we can locate our experts directly in your business. But not only are our visionary developers and highly experienced technical experts at your side wherever you are in the world. Local distributors in our comprehensive global network are always nearby to assist whenever you need us. At HellermannTyton, excellence in development competence goes hand in hand with expertise in sales and logistics. Integrate the advantages we offer into your own development projects. Tell us where you want to take your industry, and we will deliver the solution to help you get there.