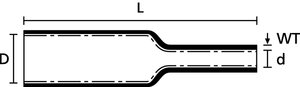

Heat Shrinkable Tubing Thin Wall with Adhesive Liner 3:1 L=1.2m 19/6 black

Številka proizvoda 315-13005

| TA37 19-6-PO-X-BK

|

Copied

- Thin wall adhesive lined heat shrink tubing

- Halogen free

- Flame retardant

- Combination of these three (halogen free, adhesive lined and flame retardant) product properties is unique

- Low smoke generation

- Low generation of toxic gases and corrosive acid

Zahtevajte svojo individualno ponudbo zdaj

Zahtevajte ponudbo

More products in this product group:

| Application | TA37 shrink tubing has a low smoke index and excellent flame retardant properties to meet strict fire security standards in electrical insulation. |

| Behaviour At Low Temperature | not cracking |

| Behaviour at Heat Shock | not fluid, not dripping, not cracking |

| Behaviour at low Temperature test method | SAE-AS23053 |

| Colour | Black (BK) |

| Heat Aging Test | 168h/138°C |

| Heat Shock Test | 4h/225°C |

| Material | Polyolefin, cross-linked (PO-X) |

| Minimum Tensile Strength At Heat Aging | 7.3MPa |

| PART DESCRIPTION | TA37 19-6-PO-X-BK |

| Pack Cont. | 1.2m |

| Package Content packed in | pcs. |

| Printable | No |

| Product Family | TA37 – thin wall adhesive lined |

| Product Group | Heat shrinkable tubing 3:1 - Flame retardant |

| Short Description | Heat Shrinkable Tubing Thin Wall with Adhesive Liner 3:1 L=1.2m 19/6 black |

| Shrink Ratio | 3:1 |

| Type | TA37 19-6 |

| Variant | Thin-Wall |

| With inner glue (Yes/No) | Yes |

| Adhesive | Hot melt adhesive |

| Dielectric Strength | 19.7kV/mm |

| Dielectric Strength test method | ASTM D876 |

| ELV compliant (Article 4 - 2) | YES |

| Elongation at break | 200% |

| Elongation at break test method | ASTM D638 |

| Halogen-free | Yes |

| Hazardous Goods | No |

| Limited Fire Hazard | Yes |

| Min. Shrink Temperature - °C | +120 °C |

| Operating Temperature | -40 °C to +105 °C |

| ROHS compliant | Yes |

| Self extinguishing | Yes |

| Softening Point Adhesive | +85 °C |

| Specifications | conforms to BS6853, conforms to LUL E1042:A6, DIN EN ISO 4892-2, EN 45545-2, IEC 60068-2-5:2018, Test Sa2 (Solar radiation test) |

| Specifications |

|

| Tensile Strength | 10.4MPa |

| Test Method Tensile Strength | ASTM D638 |

| UL Listed (US and Canada) | No |

| UL Listed (US and Canada) | No |

| UL Recognized (US and Canada) | No |

| UL Recognized (US) | No |

| Volume Resistance | 10¹³ Ω cm |

| Water Absorption | 1.0% |

|

|

|

| Country of Origin | JP |

| Customs Number | 39173200 |

| GTIN-13 / EAN | 4031026444574 |

| Packaging 1 - Height (m) | 0.04m |

| Packaging 1 - Length (m) | 1.36m |

| Packaging 1 - Qty | 15 |

| Packaging 1 - Type | bag |

| Packaging 1 - Volume (m³) | 0.012512m³ |

| Packaging 1 - Weight (kg) | 1.155001kg |

| Packaging 1 - Width (m) | 0.23m |

| Packaging 3 - Height (m) | 0.26m |

| Packaging 3 - Length (m) | 1.27m |

| Packaging 3 - Qty | 75 |

| Packaging 3 - Type | carton |

| Packaging 3 - Volume (m³) | 0.0859m³ |

| Packaging 3 - Weight (kg) | 6.615kg |

| Packaging 3 - Width (m) | 0.26m |

| Packaging 4 - Height (m) | 0.964m |

| Packaging 4 - Length (m) | 1.2m |

| Packaging 4 - Qty | 450 |

| Packaging 4 - Type | pallet |

| Packaging 4 - Volume (m³) | 0.925m³ |

| Packaging 4 - Weight (kg) | 88.79kg |

| Packaging 4 - Width (m) | 0.8m |

Argentina

Argentina Australia

Australia Brazil

Brazil Bulgaria

Bulgaria China

China Czech Republic

Czech Republic Denmark

Denmark Finland

Finland France

France Germany

Germany Hungary

Hungary India

India Italy

Italy Netherlands

Netherlands North America

North America Norway

Norway Poland

Poland Portugal

Portugal Romania

Romania Russia

Russia Singapore

Singapore Slovenia

Slovenia South Africa

South Africa South Korea

South Korea Spain

Spain Sweden

Sweden Switzerland

Switzerland Türkiye

Türkiye United Arab Emirates

United Arab Emirates United Kingdom

United Kingdom

Prenos

Prenos

H6100

391-00110

H6100

391-00110 TA37 3-1-PO-X-BK

315-13000

TA37 3-1-PO-X-BK

315-13000