Avoiding Titanic cable management mistakes

We’ve put together a few “Titanic“ cable management mistakes to avoid.

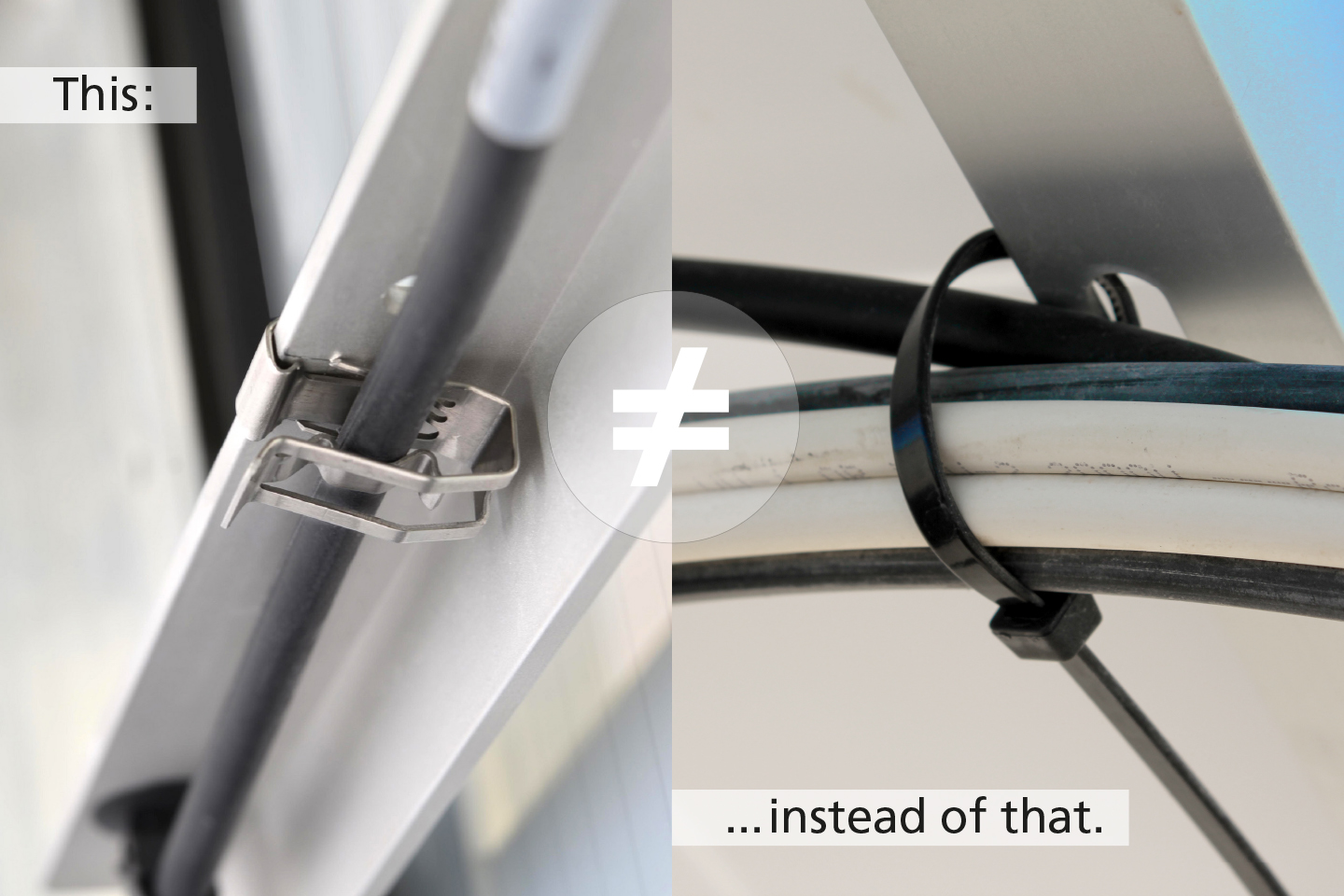

1. Sail around the perfect storm with a perfect cable tie angle

1. Sail around the perfect storm with a perfect cable tie angle

Appearances deceive in this picture. It all looks so neat and tidy, doesn’t it? But if you look closely you see that the cable tie is inserted directly into a hole on the frame. A perfect storm of maintenance and danger to human life is brewing here. The problem with threading cable ties into module mountings or grounding holes is that edges are often sharp and any movement such as from trackers, wind, or temperature change will damage the cable and cause faults. Use suitable retainers (e.g. Edgeclip, MSC series, LOC series, PBM9) to keep the cable tie at the perfect angle, 90 degrees to the cable. This will go a long way towards avoiding damage.

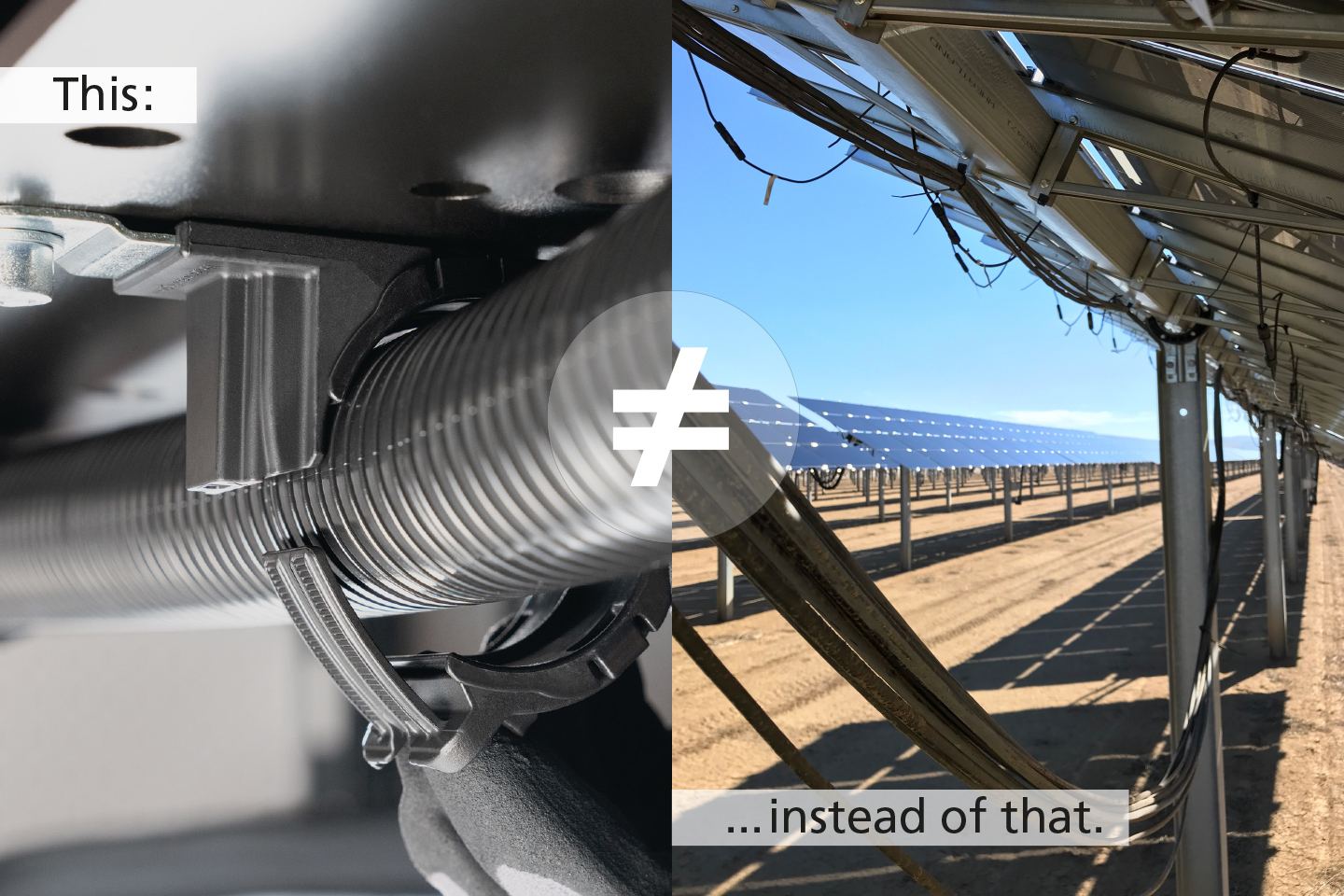

2. Dangerous dangling

Now this really is a worst case scenario, and if livestock happen to wander beneath these panels they might quite literally be in for the shock of their lives – and not just because they’ll be aghast at this sloppy cable management.

Here installers might save on initial outlays, but without proper cable management they can expect the weight of the cables to pull on junction boxes. The weight of any snow or ice on the cables, or motion, is going to make this problem even worse. Over time, the undergrowth will also have to be cut. Our bet is that one day a cable will be cut too. Our solution? Consult one of our experts, who can advise on materials and various cable and wire management options. The installation owner will appreciate it. The livestock will appreciate it. And the unfortunate person looking after the undergrowth won’t find him- or herself suddenly holding the ends of a cut cable end in each hand.

3. Not all cable ties are sun-worshippers

Yes, we all like fantastic weather, and generally the sunnier the better, but our testing shows that cable ties unsuited to high UV exposure will simply fail over time. You end up with a situation in this picture.

Let’s take a close look at things you need to consider here. First of all, you have to decide whether to use plastic or metal. You also should think about chemical resistance. We never recommend plastic coated metals, as movement (e.g. wind, waves, trackers, temperature changes) and other environmental factors can easily take their toll on the outer coating, with the risk of arcing or inverter grounding faults. Sharp edges are also a problem with some metal retainers (we’ve got solutions that avoid this). And then you as an installer want to work with metal clips that are user-friendly to avoid repetitive strain (we have some options here too). Whenever local regulations allow, suitable plastic can be the preferred solution. We have lots of solutions based around UV-resistant polyamides. Ask us and we’ll suggest ways to maximize lifetime, even in harsh conditions.

4. “Unzipping” is not cool cable management

“Unzipping” describes what happens when fixing points are at the wrong interval. The weight of the cable gradually causes it to dislodge or “unzip” along the length and breadth of a solar installation. This causes all kinds of problems: sagging cable, the dangerous dangle we mention in Mistake No. 2, and more. So, what’s the solution? Either you reduce the weight of the cable (this is not really an option), or you increase the number of fixing points. Just one of our tips is to use the Ratchet-P clamp series you see on the left, which can handle a wide range of diameters. That makes it really versatile for holding bundles of cable in place.

Contact our experts

Are you interested in finding out more?

Our experts are always ready to offer help and advice, and answer any questions.