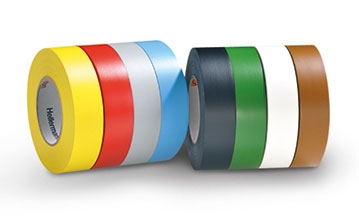

With HelaTape, HellermannTyton offers engineers, designers and electricians a wide range of PVC- and rubber-based insulation tapes that are ideal for long-lasting insulating, attaching, bundling, sealing and marking cables. Our colored tape in different sizes and materials supports the professional use in a wide variety of areas: whether as a fast help for repairing electrical wires and cables, as a tool for sealing connection points, as a visual warning for provisionally laid cables or as a way to color-code cables.

Our adhesive tapes can be used in many ways: traditionally for insulation, as conductive tapes for shielding or for arc and fire protection. Our portfolio also includes self-welding and textile tapes. All products are characterised by different mechanical properties, such as high tensile strength and abrasion resistance, electromagnetic properties, or air- and water-tight seals. This diversity allows the HelaTape family to fulfil most demands.

The use of high-quality material provides optimum protection against dust, UV radiation, moisture, dirt, acids, alkalis and solvents – and is possible in a broad range of temperatures. It is tough to beat the efficiency, speed, durability and safety of taping, sealing and padding work. The high product quality is also guaranteed by various certifications.

Watch this video to see how you can quickly and easily repair broken cable jackets with the self-amalgamating HelaTape Power 650. Thanks to the complete and airtight sheathing, dirt and water are safely kept away from the cable.

Learn more about our professional insulation tape range:

Based on a vinyl film and coated with a balanced combination of high quality rubber-adhesion, HelaTape Flex is characterised by excellent performance and durability. The PVC tapes can be used for insulation, protection, bundling, maintenance, colour coding and many other applications. The range also includes premium tapes with excellent characteristics for all types of weather and superior performance in cold conditions.

HelaTape Shield is used for rebuilding strand and insulation shields on high-voltage splices and for shielding all types of electrical connections. The special knit design allows easy application and provides good electromagnetic shielding.

HelaTape Power 410 is an unsupported, liner less, elastomeric tape which offers superior arc and flame resistance. It creates a thermally insulating residue when exposed to fire and is also water, chemical and UV resistant.

HelaTape 420 is a woven glass fabric tape with high tensile strength and abrasion resistance with a service temperature rating of 130°C.

HelaTape Power 600, 650, 800, 810, 820 and 900 are self-amalgamating mastic tapes without glue and are classified for low, medium and high voltage applications. Self-amalgamating tapes are used for air-tight and water-tight sealing.

• Polyvinyl chloride insulating tape in different colours in different colours – black, white, blue, red and many more

• Used for insulation, protection, fixing, maintenance, colour coding and more

• Good resistance to abrasion, moisture, chemicals, and varying weather conditions

• Highly flexible with good adhesion level

• Harnessing of cables and wiring

• Suitable for mechanical and electrical applications up to 1 kV

• Meets IEC 60454-3-1-5/F-PVCP/90 requirements

• Flame retardant

• Special high level adhesion

• Flame retardant

• Suitable for mechanical and electrical applications up to 1 kV

• Additional thickness for quicker layering and added abrasion resistance

• Special high level adhesion

• Flame retardant

• Suitable for mechanical and electrical applications up to 1 kV

• Additional thickness for quicker build-up and added abrasion resistance

• Particularly suitable for higher mechanical resistance

• Thickness in total 0.40 mm

• Very good for quicker layer build-up

• Special high level adhesion

• Flame retardant

• Suitable for mechanical and electrical applications up to 1 kV

• Multi-weather, professional grade, self-adhesive vinyl insulating tape

• Excellent performance and durability over wide temperature range from -18°C to +105°C

• Meets IEC 60454-3-1-11/F-PVCP/105 requirements

• Used for insulation, protection, fixing, maintenance, colour coding and more

• Pressure sensitive high quality rubber based adhesive

• Performs continuously at low temperature environment

• Excellent resistance to abrasion, moisture, chemicals, corrosion and UV exposure

• For all wire and cable splices up to 1 kV

• Protective jacketing for low, medium and high voltage splices and repairs

• Harnessing of wires and cables

• For indoor and outdoor applications, for example in the HVAC sector

• Flame retardant

• RoHS compliant

• Multi-weather, professional grade, self-adhesive vinyl insulating tape with higher thickness for more mechanical and electrical protection

• Pressure sensitive and aggressive high quality rubber based adhesive

• Performs continuously at low temperature environment

• Excellent resistance to abrasion, moisture, chemicals, corrosion and UV exposure

• For all wire and cable splices up to 1 kV

• Special adhesive

• Excellent protection against corrosion

• Complete environmental, mechanical and electrical protection

• Highly resistant to UV, water, oil, most chemicals, bacteria and fungus

• Used for pipes, tubes, and conduits in outside and underground

applications

• Self-amalgamating shielding tape made from ethylene propylene rubber

• Electrostatic shielding for high voltage splices and terminations

• Excellent conducting properties

• Prevents corona effect

• Moisture and UV-resistant and easy to apply

• Copper shielding braid, tin-plated

• Quick and easy to use due to copper knit-mesh design

• Excellent conformability

• Good electromagnetic properties

• Used for splices and terminations of shielded cables

• Unsupported, linerless, elastomeric tape

• Superior arc and flame resistance

• For cable protection in all type of applications

• Excellent flexibility and conformability for easy application

• Creates insulating residue when exposed to severe flame conditions

• Water, chemical and UV resistant

• Woven glass fabric tape with thermosetting adhesive

• High tensile strength

• Excellent tear and abrasion resistance

• Operating temperature rating of 130°C

• Self-amalgamating tape for insulating and jacketing splices up to 69 kV

• Halogen-free with outstanding corona, ozone and UV-resistance

• Void-free, electrically stable layering

• Amalgamates quickly

• Protects bus bar components

• Excellent moisture, corrosion and chemical resistance

• Ideal moisture seal for water-proofing applications

• Ethylene rubber-based, high-voltage, linerless, self-bonding tape

• Excellent electrical, chemical and physical properties

• Building stress cones and jacketing of terminations, bus bars and joints

• High thermal conductivity

• Quicker application due to linerless design

• Uniform and void-free layering

• Excellent stretch to conform to the most complex shapes and contours

• Flame retardent and UV resistant and compatible with all extruded cable insulations

• Self-amalgamating low voltage tape made of rubber

• Primary insulation at not more than 1 kV

• Easily conforms to irregular shapes and surfaces

• Void-free electrically stable layering

• Compatible with all extruded dielectric cable insulations

• Recommended use in conjunction with HelaTape Flex for outer jacketing

• Self-amalgamating, low voltage insulating compound

• For quick, void-free insulation layering

• Easily moulded by hand to conform to irregular shapes

• Perfect adhesion to metal, all types of cable insulations and jackets

• Excellent thermal stability

• Provides excellent moisture seal

• Resistant to salt water, oil and corrosive chemicals

• Recommended use in conjunction with HelaTape Flex for outer jacketin

• Self-amalgamating, chemically cross-linked silicone rubber tape

• Triangular cross-section with centre line for precise half-overlapping

• Resistant to creepage and surface erosion

• Fuses into solid mass after application

• Weather, UV and Oil resistant

• No adhesion coating

• Recommended use for high temperature silicone insulated cables

• Ethylene rubber-based, high-voltage tape

• Superior electrical, chemical, mechanical and thermal properties

• Fuses quickly for void-free, electrically stable layering

• Insulating and jacketing splices on power cables up to 138 kV

• Building stress cones and termination jackets for cables up to 35 kV

• Outstanding corona, ozone, chemical and corrosion resistance

• Withstands UV and cable impregnants

HelaTape Tex cloth tapes are extremely strong in the longitudinal plane and are easy to tear with the fingers in the transverse direction. The range is ideal for protecting, marking, fixing, bundling, patching and repairing. HelaTape Tex is weather-resistant, water-repellent and can be removed residue-free, which is an important characteristic for stage and lighting construction, events and exhibitions.

• High quality PE-coated cloth tape

• Total thickness of 0.31 mm for high tensile strength

• Matt surface finish for use in stage constructions and for exhibitions to avoid light reflections

• HelaTape Tex can be removed without residues due to high quality rubber based adhesion

| Product Name | Product Description | Tape Thickness (mm) | Width (mm) | Length | Typical Applications |

| HelaTape Flex 15 |

General purpose vinyl insulating tape in many different colours (black, white, red, blue and much more)

|

0,15 | 15,0 | 10,0 m |

Protective jacketing, harnessing, bundling, colour coding

|

| HelaTape Flex 20 | General purpose vinyl insulating tape with higher thickness | 0,2 | 19,0 | 20,0 m |

Protective jacketing, harnessing, bundling

|

| HelaTape Flex 23 |

General purpose vinyl insulating tape with higher thickness

|

0,23 | 19,0/ 38,0 | 33,0 m |

Protective jacketing, harnessing, bundling, abrasion protection

|

| HelaTape Flex 40 |

General purpose vinyl insulating tape with very high thickness

|

0,40 | 50,0 | 30,0 m |

Protective jacketing, harnessing, bundling, abrasion protection

|

| HelaTape Flex 1000+ | All-weather, professional grade vinyl insulating tape, highly conformable, many colours (black, white, red, blue and much more) | 0,18 | 19,0/ 50,0 | 6,0 m/ 10,0 m/ 20,0 m/ 33,0 m |

Primary insulation, protective jacketing, colour coding

|

| HelaTape Flex 2000+ |

All-weather, professional grade vinyl insulating tape, highly conformable, extra thick

|

0,21 | 19,0/ 25,0/ 38,0 | 6,0 m/ 20,0 m/ 33,0 m | Primary insulation, protective jacketing, abrasion protection |

| HelaTape Wrap 25 |

All-weather anti-corrosion vinyl tape with special adhesive

|

0,25 | 25,0/ 38,0/ 50,0/ 100,0 | 30,0 m | Protection against corrosion, UV, water, oil, most chemicals, bacteria and fungus |

| HelaTape Shield 310 | Self-amalgamating tape with excellent conducting properties | 0,76 | 19,0/ 38,0 | 4,6 m/ 9,1 m | Cable shield continuation for high voltage connections. |

| HelaTape Shield 320 | Copper shielding braid, tin-plated | 25,0 | 4,6 m |

Continue electrostatic shielding

|

|

| HelaTape Power 410 | Elastomeric, linerless tape with superior arc and flame resistance properties | 0,76 | 38,0 | 6,0 m | Fire and electric arc proofing on high-energy cables |

| HelaTape Power 420 | Woven glass fabric tape with a service temperature rating of 130°C | 0,18 | 19,0 | 20,0 m | Short-circuit proof bundling of medium voltage cables |

| HelaTape Power 600 | Low voltage self-amalgamating tape, suitable to irregular shapes and surfaces | 0,76 | 19,0/ 38,0 | 6,7 m | Insulation of low voltage wire splices and split bolt connections |

| HelaTape Power 650 |

Low voltage self-amalgamating tape for quick, void-free insulation layering

|

3,20 | 38,0 | 1,5 m |

Covering split bolts, bus bar edges and connections, provides excellent moisture seal

|

| HelaTape Power 800 |

Self-fusing silicone rubber tape, resistant to creepage and surface erosion |

0,51 | 25,0 | 9,1 m |

Insulation of high temperature silicone cable and terminating high voltage cables. Weather, UV and oil resistant

|

| HelaTape Power 810 |

High voltage self-amalgamating insulating and jacketing tape |

0,76 | 19,0 | 9,1 m |

Primary electrical insulation for cables through 69kV

|

| HelaTape Power 820 |

Linerless high voltage self-amalgamating insulating and jacketing tape

|

0,76 | 19,0 | 9,1 m |

Primary electrical insulation for cables through 69kV

|

| HelaTape Power 900 | Extra high voltage self-amalgamating insulating and jacketing tape | 0,51 | 19,0/ 25,0/ 38,0 | 9,1 m | Primary electrical insulation for cables through 138kV |

| HelaTape Tex |

PE-coated cloth tape with matt surface finish to avoid light reflections | 0,51 | 12,0/ 15,0/ 19,0/ 25,0/ 50,0 | 25,0 m/ 50,0 m |

Bundling, fixing, identification, marking and abrasion protection

|

There are many kinds of tape used for various purposes. Electrical tape is specifically designed for electrical applications as it insulates and protects electrical wires and connections. It is made from materials that are non-conductive and can withstand electrical currents without causing short circuits. It is also heat-resistant and provides protection against moisture. Finally, electrical tape has an adhesive that provides good adhesion to itself and to electrical wiring.

There are several types of electrical tapes available, each designed for specific applications and with varying properties to suit different needs.

The colours of electrical tape are often used for colour coding purposes in electrical and wiring applications. Different colours can signify specific functions, phases, or types of wires, making it easier to identify and work with electrical systems.

Electrical tape prevents electrical current from flowing through it by creating a barrier between conductive materials, such as the wires, and the surrounding environment. This barrier is created with materials that have a high electrical resistance such as vinyl, PVC, or rubber. The electrical tape is tightly wrapped around a wire or connection, forming an isolation as well as an insulation layer.

Electrical tape can provide a certain level of protection against shocks. It creates a non-conductive barrier that helps to prevent electrical current from escaping, reducing the risk of accidental contact and shocks. However, the effectiveness depends on the quality of the tape itself and how it is applied.

When choosing an electrical tape, it is important to consider factors such as the intended application, environmental conditions, voltage levels, and the specific properties required for proper insulation and protection. Factors to consider include: