Cable tie guns are not all the same – and for good reason. While some cable tie processing tools are suitable for areas that are difficult to access, other cable tie guns must function without electricity when used in mobile applications. There are also the durability and efficiency requirements of modern series production to consider: Cable tie tools must always be reliable and convenient, even during long-term use.

That’s why HellermannTyton offers a comprehensive range of cable processing tools, including manual and pneumatic cable tie guns plus unique automatic cable bundling tools.

Cable tie guns are the ideal solution for optimum tensioning and cutting of cable ties flush to the cable tie head. They eliminate the sharp snags that conventional wire cutters leave behind. Cable tie guns also help accelerate bundling processes and professionalise the tying of cable ties made from various materials and sizes.

See in this video how to cut cable ties safely and without sharp edges using a professional cable tie gun. The EVO7 cable tie gun featured is one of the most lightweight yet robust manual cable tie enough for industrial processing of cable ties:

The electrically operated Autotool 2000 CPK bundling tool is a leader in terms of process reliability and automation. It works fully automatically and accelerates cable tying processes considerably. Bundling, threading, tensioning and cutting are done at the touch of a button – with constant quality. This automatic bundling tool makes faster and more effective processing possible.

Your advantages:

Suitable accessories:

Tutorial video:

HellermannTyton is the proud winner of the 2020 Ergonomics Award for its Autotool 2000 CPK fully automatic bundling system.

An independent jury at the German Ergonomics Competence Network – ECN (Ergonomie-Kompetenz-Netzwerk e.V. ) awarded the tool the highest commendation in the category "Handheld Tools".

The award jury also highlighted the positive ergonomic benefit of functions such as "Defined loop diameter", "Tape overhang", "Tension-free cutting", "Continuous operation" and an "AND link" (triggering of the tool is only possible if signal is given by two different sensors).

Click here for more information.

The electrically operated Autotool System 3080 tool enables waste-free tying of bundles at various diameters. The tool can be used both stationary and flexibly. A special device available for the Autotool System 3080 allows it to be integrated fully into automated production lines.

The tying of foot parts with a cable tie gun can be fully automated.

Your advantages:

Accessories:

From a handy hanging device to automatic production in a robot: By using our Autotool System 3080 you can save a lot of time.

Discover now the different possibilities for your application: here in this video.

With the EVO family of cable tie guns, HellermannTyton offers you the most ergonomic and durable manual cable tie tools on the market. Comfort and function are combined to provide high-quality repeatable cable tying results at a wide variety of tension settings.

The technology in the EVO7 and EVO9 cable tie tools significantly reduces the amount of force required to tension and cut cable ties. The EVO family cable tie processing tools feature quick adjustment for changing between tension setting ranges.

Your advantages:

With its lightweight, ergonomic design, the MK9SST cable tie gun is an ideal tool for applying the MBT series stainless steel cable ties. Although it is used for applying stainless steel cable ties, the MK9SST cable tie gun enables work to be carried out without operator fatigue.

For easier handling the tensioning is fully adjustable by means of a quick two level control with an additional fine setting. This feature means that damage to the bundled materials is easily avoided. The cable ties are automatically cut off flush with the head when the preset tensioning level has been reached.

The MK3PNSP2 cable tie gun is pneumatically operated. It is characterised by its high bundling speed and is often used in large-scale series production, on wiring harness assembly lines and in cable assembly.

The processing of cable ties is very easy with this cable tie gun: A push on the button and the cable tie is tensioned and automatically cut directly at the head. The smooth cut edge prevents injuries.

The strap cut-off is ejected automatically to eliminate process interruption.

The cable tie cutter EVO cut is used for the safe removal of plastic zip ties. So fare cable ties have been removed with a standard side cutter that runs the risk of damaging the cable, with the new EVO cut cable tie removal tool the wire insulation remains intact.

The EVO zip tie cutter is ideally suited for large-scale industrial applications in the field of cable assembly.

It is made of a lightweight ergonomic plastic housing of glass-fibre reinforced polyamide. That’s why it is easy to operate with one hand.

One reason why the bundled goods remain unharmed are the precisely adjusted blades.

However, to ensure that only the cable tie is cut and not cable sets, the matching nosepiece is also required depending on the zip tie width and thickness.

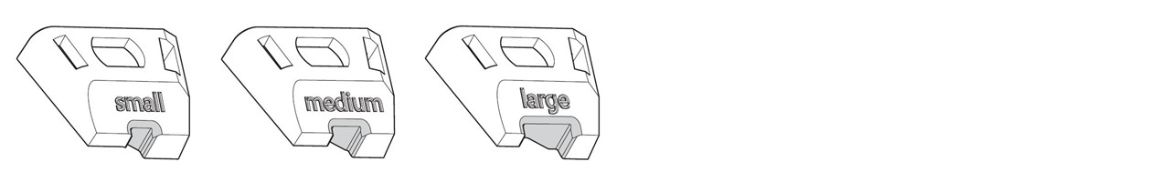

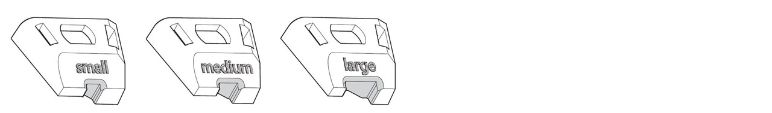

For this reason, our zip tie cutter is available with three different nosepieces:

Here you find an overview about the nosepiece sizes you can use to cut HellermannTyton cable ties safely:

| Nosepiece | max. width tie | max. thickness tie | T-Series | OS-Series | X-Series | Q-Series | CTT-Series | PEEK |

| SMALL | 3,6 mm | 1,2 mm | T18 T30 |

T18ROS T30ROS |

X20 | Q18 Q30 |

CTT20 | PT2A |

| MEDIUM | 4,8 mm | 1,3 mm | T40 T50 T80 |

T50ROS | X80 | Q50 | CTT60 | PT3B PT220 |

| LARGE | 7,8 mm | 1,8 mm | T120 T150 |

T120ROS | X120 | Q120 | / |

/ |

All three nosepieces are securely attached to the EVO cut and can be easily changed using a simple push system.

A light press on "Push" releases the locking mechanism and the front cap can be pulled off. The front nosepiece can be put back on just as easily.

Our in-house team of developers can also implement individual cable tie tool requirements for you – from the smallest cable tie guns to automatic bundling systems.

In collaboration with you, we can make specific adjustments or develop completely new cable tie bundling tools. At our site in Tornesch, Germany, HellermannTyton technicians manually install and service some 500 parts per automatic cable tie gun.

Fitters and installers can rely on cable tie processing tools from HellermannTyton to be of the highest quality and effectiveness.

TLC technology stands for Tension/Lock/Cut. This bit of technology makes all the difference in the EVO7 and EVO9 cable tie guns.

1. Tension

The cable tie is tensioned to the preselected tensile force.

2. Lock

Once the selected tensile force is reached, the cable tie gun automatically clamps the cable tie strap. The manual force usually required to keep the cable tie tensioned is no longer required.

3. Cut

All the user has to do is pull the cable tie gun lever back gently. Very little force is required for the flush, smooth cut.

The benefit of the TLC technology in the EVO cable tie tools is immediately obvious to anyone used to conventional cable tie guns. Locking the tensioned strap before the cut reduces the mechanical strain on the tie, the blade and the operator’s muscles. The lack of recoil helps minimise repetitive strain injuries when operators manually tie thousands of cable ties per shift.

Automatic bundling systems such as the Autotool 2000 CPK and the Autotool System 3080 are suitable wherever very large numbers of cable ties have to be processed and constant quality guaranteed - e.g. in wiring harness assembly, in the automotive industry, in industrial plants or in the packaging sector.

Cable tie guns are often used when cable ties are processed in large quantities. The aim is to make it easier to tie large quantities of cable ties quickly and cut off the excess strap flush to the tie head. Cable tie guns also help tension and cut cable ties in hard-to-reach spaces, or at awkward angles, using one hand.