The range of HelaCon push-in wire connectors is used for fast, easy and reliable termination and distribution of cable and conductings in electrical housing applications. They may be used within a typical range of housing tension up to 450 volts. A huge variety of input poles allows high flexibility in application depending on the number of conductors and available space.

Cross-sections of up to 2,5 mm² can conveniently be processed and allow the use of thicker ladders when a voltage drop occurs. The way of cable distribution and branch junctionsvaries from country to country due to the different types of wires, diameters, colours, junction boxes and mounting systems in use.

The newly developed double-head spring of our HelaCon Plus Mini connection terminal makes it particularly easy for you, as the push-in wire can be inserted into the terminal with considerably less effort – especially practical in hard-to-reach areas or when working overhead. Thanks to the transparent housing, you can also check at a glance whether the wire is correctly seated. See how easy it works in this video.

No matter how distinct the individual requirements are – the HelaCon wire connector series offers the best solution for every task – worldwide. Different colour codes help to easily differentiate the sizes of the push-in wire connectors. All cable entries are in a row on one side. A separate power test entry on the front guarantees safety during application, installation and maintenance. Any conductor with cross-sections between 0.5 and 2.5 mm² can be used at the same time, without impact on the adjacent junction.

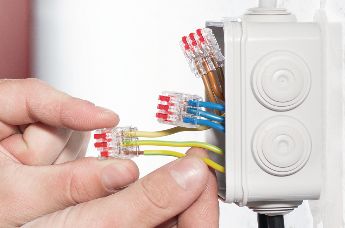

Being compact in size the push-in wire connectors HelaCon fit perfectly in tight spaces and can generally be used in all kinds of junction boxes either on-wall or flush-mounted.

The range of push-in wire connectors is used for fast, easy and reliable connection and distribution of conductors in electrical housing applications. They are designed for use in a typical range of housing tension up to 450 volts.

A huge variety of input poles allows high flexibility in application depending on the number of wire conductors and available space. Diameters of up to 2.5 mm² can conveniently be processed and allow the use of thicker conductors when a voltage group occurs.

Being compact in size they fit perfectly in tight spaces and can generally be used in all kinds of junction boxes either on-wall or flush-mounted.

The HelaCon Easy cable crimps are exclusively designed for use with solid wire up to a diameter range of 2.5 mm². Bent, stranded or fine-stranded wire conductors may not be used.

Wire Range (cULus): 22-12 AWG Sol. Cu / 22-14 AWG Tin-dipped Str. Cu

• Make sure that power is turned off before installation

• Use bulk copper cables only

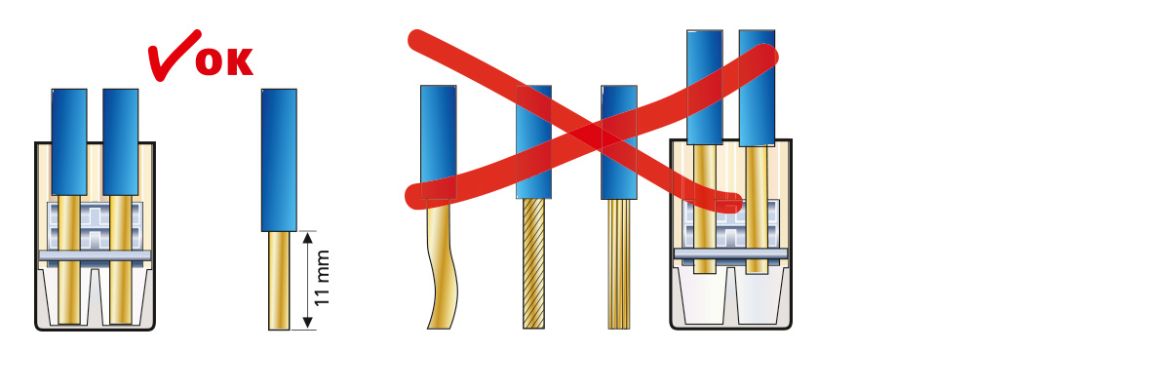

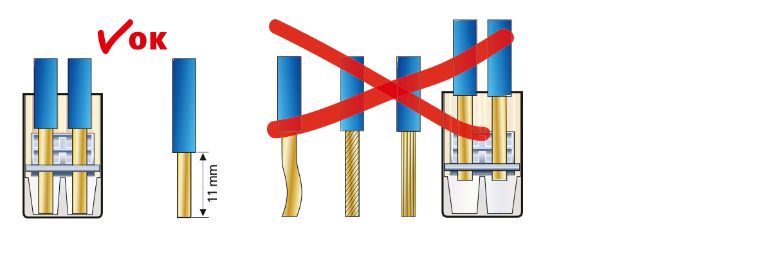

• Strip them off approximately 11 mm

• Insert them completely into the wiring connector

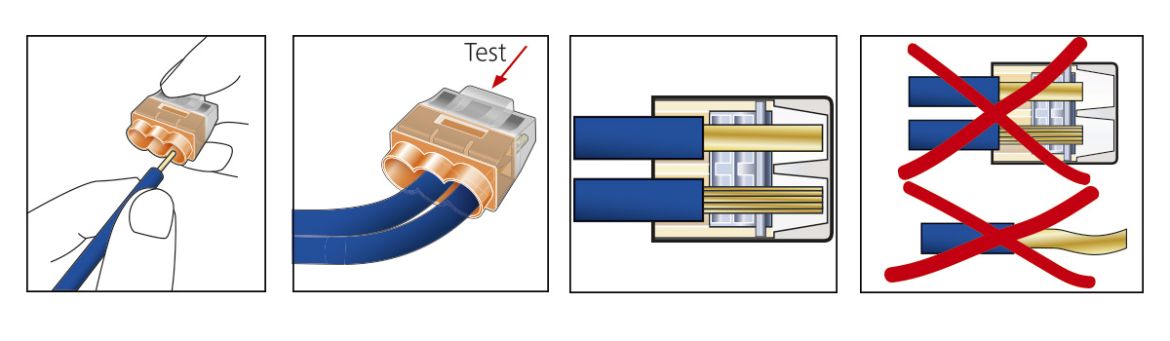

• Use voltmeter via separate test entry

• To change or correct a wire, hold and twist it alternatively left and right while pulling the wire connector

HelaCon Plus Mini is a sophisticated push-in wire connector for professional cable links in electrical housing applications.

The newly developed double spring allows easy processing and will support installers especially in difficult situations like overhead work. This ensures proper fixing that can optically be checked through the transparent housing.

Different colour codes provide a comfortable identification of the different connecting clamps. A separate voltage test entry on the front guarantees safety during application, installation and maintenance.

The HelaCon push-in wire connectors made of polycarbonate (PC) are used for fast, easy and reliable connection and distribution of ladders in the field of electronic installation.

The connections can be used in all kinds of junction boxes either on-wall or flush-mounted.

HelaCon Plus Mini offers the best possible solution when convenient processing and maximum safety is required.

• Do not work under load

• Use only sturdy and stranded copper wires

• Strip length 11 mm

• Push-in the full stripped length into the cable connector – check the connection through the transparent housing

• Use easy access voltage test entry at the rear side

• Disconnecting the wiring: Hold the wire and twist the wire connector to the left and to the right

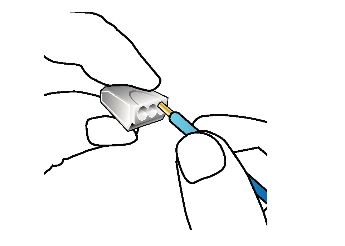

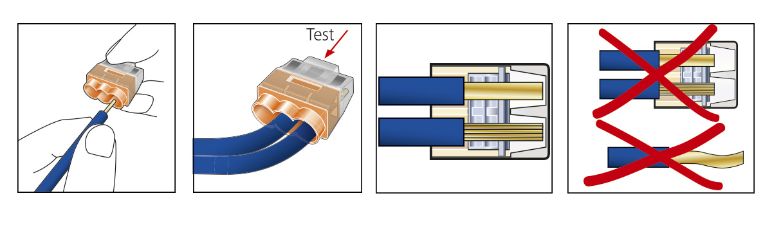

Picture 1: The double spring allows easy push-in of the conductor.

Picture 2: A separate test entry on the rear side allows the use of a voltage meter.

Picture 3: Solid wires 0.5 - 2.5 mm²

Picture 4: Stranded wires 1.0 - 2.5 mm²

Picture 5: Not for flexible wires suitable

A typical application is lighting system, where the massive ladder from concealed cabling has to be connected to a flexible conductor for lighting. The 2/1 variant allows the looping through of the supply lines for additional devices.

The conductor on the output/lighting side can easily be inserted by pressing the locking mechanism and can be released in the same way at any time.

The lighting side can carry any kind of conductor and makes HelaCon Lux coupling clamps also useful to connect devices that carry flexible connecting cables like control devices e.g. for blinds, fans and other drives.

• Best suitable to connect solid with flexible wire

• Combines push-in connector with lock/unlock spring mechanism

• For fine-stranded conductors at lighting input

• Use with typical voltage current of 450 V / 24 A

• Either one or two inputs for massive conductor

• Very flexible application

• Low insertion force

• Tool-free application for easy, time-saving, safe connection

• Especially for overhead work and when wires are difficult to access

Our HelaCon Plus Mini and HelaCon Lux connectors are now also available in practical Blister packs. These sets, which you will find in selected DIY stores, contain between 10 and 20 products and are enable quick and easy assembly of low-voltage electrical conductors in buildings.

HelaCon releasable connectors provide the best solution for joining solid, stranded and fine-stranded wires. The push-in connector can be used with solid wires without opening the lever – just push in the wire. It fits a wide clamping range of 0.2 mm² - 2.5 mm². This new connector is fully re-useable – no screwdriver is needed. The proper fixing can be visually checked through the clear shell. All in all this compact size connector is an allrounder for all types of wires.

• Universal push-in wire connector for solid, stranded and fine-stranded wires

• Solid wires simply plug in – no need to open lever

• Compact size

• Wire sizes: 0.2 mm² - 2.5 mm²

• Separate voltage test entry on the bottom

• Fully re-useable - no screwdriver required

• For proper fixing that can be visually checked through transparent housing

• Safe application, assembly and maintenance

The HelaCon push-in connectors are used for fast, easy and reliable connection and distribution of conductors in the field of electrical installation

• Do not work under load

• Use only solid and stranded copper conducting

• Strip length 10 mm

• Push the full stripped length into the wire receptable – check the connection through the transparent housing

• Use easy access voltage test entry at the bottom

• Disconnecting the wire: Open the lever to release the desired wire

Step 1: 10 mm stripping length can be visually checked with the marking on the HelaCon Releasable wire connector.

Step 2: The push mechanism allows an easy installation of the solid conductor without opening the red lever.

Step 3: Open the lever for installation of stranded and fine-stranded wires.

Step 4: Visual verification after installing the wires through transparent housing.

Step 5: Multimeter test entry on the bottom side of the connector.

Screwless connectors in the field of house installations are used countless times every day. Although this is routine work, it requires a lot of diligence.

A tight and secure fitting is indispensable for a failure-free, long-life operation. Careless work may otherwise result in damage and overheating, in the worst case causing a hazardous situation like a fire.

The transparent housing of the new HelaCon Plus Mini wire connector series allows a fast and easy optical control of whether the conductor fits to the catch. This is a non-negligible safety factor and will expedite acceptance tests of the complete electrical installation.

The low push forces due to the latest double spring technology enables the use of single- and multicore conductings.

The free fixing of each double spring allows the concurrent use of various conductor cross-sections between 0.5 and 2.5 mm² within one connector without impact on the adjacent link.

Please note that HelaCon Plus Mini is not designed for fine-stranded wires.

A push-in wire connector is used to connect wires in a safe and secure way. Modern wire connectors, such as the HelaCon range, have built-in springs. These are designed to make it easier to insert the conductor into the terminal (which is particularly beneficial when using stranded conductors), while keeping the conductor securely in place in the terminal. With a crown clamp, on the other hand, the conductor has to be screwed in manually, which increases the risk of faulty connections and overheating. Double spring terminal blocks ensure a more user-friendly, efficient and reliable installation process.

A push-in connector is designed for long-term installations where the stripped wireend is quickly and easily inserted into the connector for a secure and durable connection. Openable connectors, like HelaCon Releasable, are designed for maintenance work and pre-installation.

HellermannTyton wire connectors have a transparent terminal housing to make it possible to visually check that the conductor is installed correctly.

Push-in wire connectors are supplied in different transparent colours according to the number of conductiors that can be connected. HelaCon Plus Mini terminal blocks are available in 6 different colours and sizes: