Our inhouse team of developers at HellermannTyton has responded quickly to new challenges in downlighting to offer the best solution for residential and industrial buildings.

Watch this video to see how SpotClip reduces heat build-up between the recessed spotlight and the insulation material and thus extends the service life of spotlights:

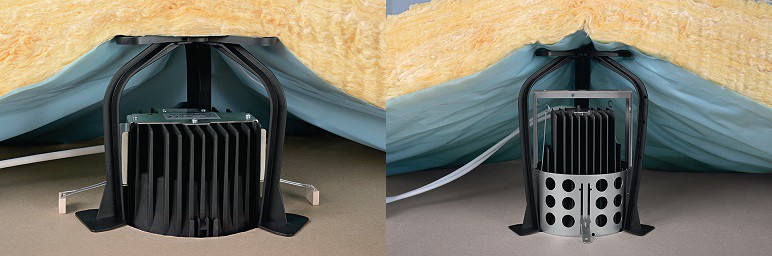

The installation of downlights in suspended ceilings, whether in residential or industrial buildings, often poses a compatibility problem between the insulation in the ceiling and the need of airflow for the downlight (risk of overheating and fire).

Indeed, to ensure a perfect insulation of buildings and energy-saving properties, it is recommended not to cut or create holes in the insulation material.

It is therefore necessary to protect the downlight with a system which is lifting the insulation material while creating space around the downlight to prevent overheating.

HellermannTyton engineers have developed a protection system in form of caps, the downlight covers SpotClip. Depending on the SpotClip, it can be used with solid or blow in insulation material. There are products available for small such as very large downlights.

SpotClip-I, SpotClip-II, SpotClip-III, and SpotClip-Box are designed for use in residential buildings. This new and innovative range of downlight covers has been developed to mount downlights in all types of suspended ceilings, ensuring the necessary safety distance to insulation material. This reduces the risk of fire and overheating to a minimum. Furthermore, the SpotClip solution increases the life span of lighting.

SpotClip-Kit and SpotClip-Plate are designed for the use in industrial buildings. This new and innovative product range has been developed to mount downlights in all types of suspended ceilings, ensuring the necessary safety distance to insulation material.

SpotClip-Plate prevents damage and cracks in ceiling plates caused by the weight of heavy downlights.

The SpotClip downlight covers have been developed to mount halogen and LED downlights in suspended ceilings. This innovative range of products offers outstanding safety and installation features and is suitable for use in both panelling and plasterboard ceilings.

The SpotClip downlight covers ensure a safety distance between downlight, damp-proof foil and insulation material and remain rigid even at higher temperatures. They prevent damage to insulation material caused by overheating and reduce the risk of fire and overheating to a minimum. Furthermore, the SpotClip solution increases the life span of lighting.

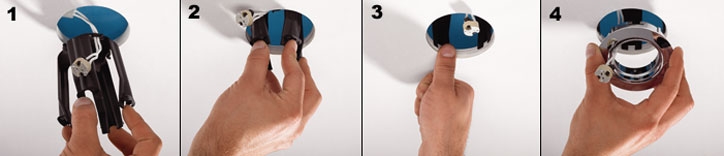

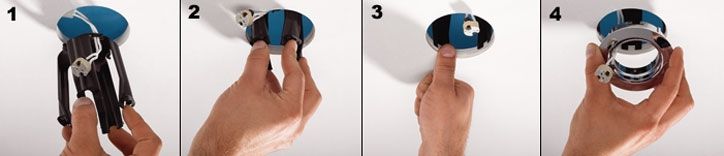

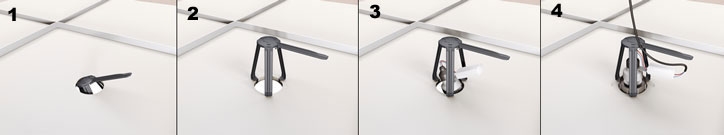

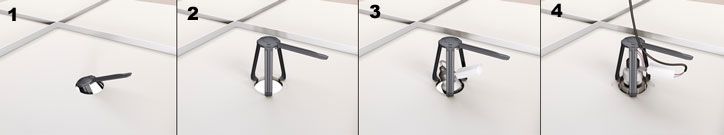

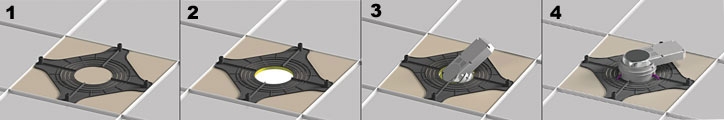

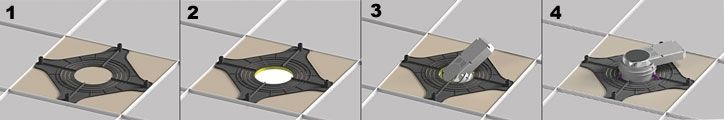

SpotClip can be installed easily during or after the construction and enables a fast replacement of bulbs.

Additional spikes at the end of the legs prevent SpotClip from shifting. The intelligent cable routing with eyelet at the top of the product holds the cable in place.

All SpotClip downlight covers passed the Glow Wire test (GWT) 960°C and are tested according the EN 60598-1, EN 60598-2-2, and NF C 15100.

Please select the right downlight cover, depending on the type of insulation material and downlight size.

• SpotClip-I for standard houses and rolled insulation material

• Maximum downlight height 70 mm

• Suitable for fixing into holes from 62 - 90 mm diameter

• Flame retardant material according to UL94-V0 - Polyamide 6.6, Glassfibre reinforced (PA66GF15%)

• For standard houses and blow in insulation material

• SpotClip-II has been developed for bulbs up to 95 mm height

• Suitable for fixing into holes from 62 - 90 mm diameter

• Flame retardant material according to UL94-V0 - Polyamide 6.6, Glassfibre reinforced (PA66GF15%)

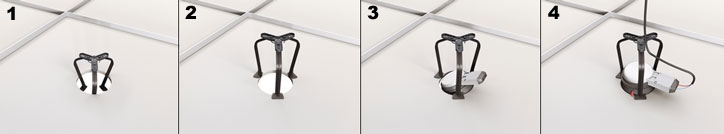

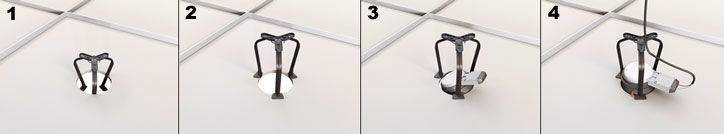

SpotClip-III has been developed to allow the use of an external power supply unit. If the downlight is without external power, the additional straight leg can be easily cut and removed manually. The straight leg helps to prevent contact between insulation and the external power supply unit of the downlight.

SpotClip-III fits all standard applications with solid insulation material. It is delivered flat with flexbile legs that are locked in place within seconds. The height of the d ownlight cover is dependent on the fixing hole diameter.

SpotClip-III is suitable for spotlight diameters from 62 mm to 120 mm and a maximum height of 115 mm.

The material is flame-retardant according to UL94-V2.

SpotClip-IV-Slim is specially designed to protect extra flat LED downlights.

The downlight cover for modern LED lamps offers easy installation and allows uncomplicated maintenance. By preventing heat build-up, SpotClip-IV-Slim can also extend the lifetime of your lights.

With an extremely low installation height of only 43 mm, SpotClip-IV-Slim is perfectly suited for the installation of flat LED spots and ideal for suspended ceilings with limited space.

Four additional and flexible tabs prevent contact between loose insulation material and the luminaire, which makes it best suited for use with bulk and blown insulation materials.

Further benefits:

SpotClip-Box has been designed especially for passive houses. The insulation material remains continuous, thus avoiding any breach in the integrity of insulation in the passive house.

SpotClip-Box is suitable for LED and compact fluorescent-lamp downlights with a diameter of up to 75 mm and a maximum height of 130 mm.It is available as a complete kit, including HelaCon Lux wire connectors and all necessary mounting components.

The material is flame-retardant according to UL94-V2 and heat-stabilised (PA66HS).

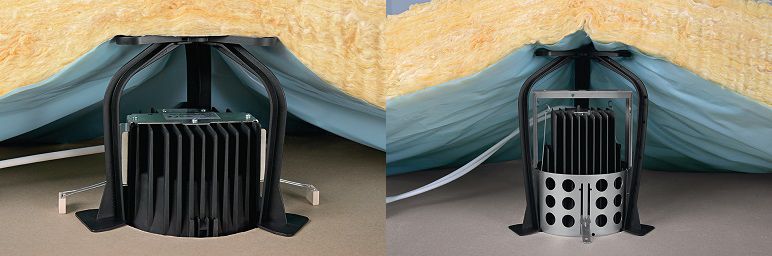

SpotClip downlight covers for industrial buildings have been designed for downlights with larger dimensions.

SpotClip-Kit and SpotClip-Plate are designed for the use in industrial buildings. This new and innovative product range has been developed to mount downlights in all types of suspended ceilings, ensuring the necessary safety distance to insulation material. SpotClip-Plate prevents damage and cracks in ceiling plates caused by the weight of heavy downlights.

SpotClip-Kit has been designed for primary use in industrial and office buildings for downlights with larger dimensions. The packaging kit consists of three legs and a mounting plate. The legs are available in two different lengths (150 mm and 240 mm). SpotClip-Kit has six selectable fixing positions in the mounting plate, making it suitable for downlights with different dimensions.

SpotClip-Kit 150 is suitable for downlights with a diameter from 100 mm up to 270 mm and with a maximum height of 140 mm. SpotClip-Kit 240 is suitable for downlights with a diameter from 170 mm up to 310 mm and with a maximum height of 230 mm. SpotClip-Kit can be combined with SpotClip-Plate.

SpotClip-Plate has been developed especially for installation in suspended grid ceilings in order to avoid damage and cracks in the ceiling plates caused by the weight of heavy downlights. The product dimensions of 592 mm x 592 mm mean that it fits perfectly into standard grid ceilings with a width of 600 mm. The pre-cut design makes it suitable for installation of the most commonly used downlights with a diameter from 75 mm to 314 mm.

Please check if your grid ceiling size corresponds to the side length of 600 mm. Depending on the manufacturer and country this can vary between 600 mm and 625 mm.

SpotClip-Plate can be used to ensure the safety distance between the downlight and insulation material. We offer three different solutions to prevent damage to insulation material caused by overheating of the bulb.

1. Place two plates on top of each other and use SpotClip-Tubes between these to achieve the required distance

2. Use SpotClip-Caps and SpotClip-Tubes to achieve the required distance between the plate and insulation material

3. Combine SpotClip-Kit with SpotClip-Plate for a fast solution

See how the downlight cover SpotClip-III is a safe and simple way to keep insulation away from downlights and external power units.

Watch to see how simple it is to evenly distribute the weight of a heavy recessed downlight using SpotClip-Plate.

Learn from our video how the adjustable downlight cover SpotClip-Kit helps you ensure a safe gap between larger downlights, vapour barriers and insulation.

No. SpotClip products are made from flame-resistant and heat-stabilised polyamide 6.6 tested according to EN 60598-1, EN 60598-2-2, NF C 15100 and UL94 V standards.

UL94 describes safety standard tests for the flammability of plastic materials used in electrical applications.

The tests determine a material’s tendency to either extinguish or spread a flame once ignited. V-0 (SpotClip I and II) indicates that burning must stop within 10 seconds; V2 (SpotClip III, Kit, Plate and Box) within 30 seconds – all at 1.5 mm thickness, Glow Wire Test 960 °C.