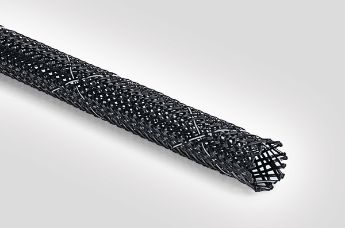

Braided sleevings is mainly used for bundling and protecting cables. Standard wrap-around sleeves, which can be applied and removed with a single handle, are ideal for this purpose.

Other applications require braided cable sleeves with special material and properties. For example, there are heat-resistant fabric sleeves that must withstand high temperatures. There is also sleeving that provides electromechanical protection or sleeves that are tear-resistant and deliver excellent protection against abrasion.

Whether you are buying for IT or industrial infrastructure, you will find the right fabric hose for your application below.

HEGMAN high temperature wire sleeves are designed for applications in demanding environments, where heat and fire protection requirements are important and mechanical protection of wire harnesses is required.

This product is commonly used in the following industries:

HEGMAN expandable mesh cable sleeves offer good abrasion resistance, are extremely flexible and are also resistant to radiation and fluids.

The fire-resistant HEGPV0 braided sleeving is designed for use in environments where fire protection is essential. It is self-extinguishing according to UL94 V0 and used for example in the following industries:

It is made from robust polyester, is very resistant to abrasion and also highly flexible.

The product variant Helagaine HEGPA66 is a flexible and expandable sleeving alternative made from highly durable polyamide yarn. This solution is particularly suitable for the requirements in the automotive and rail industries.

Helagaine HEGEMIP tubular EMI shielding sleeves combine electromechanical protection and excellent abrasion resistance.

HEGEMIP mesh cable braids are expandable and extremely flexible: Even bends of more than 90° are not an issue. This makes them perfect for applications where space is limited or for applications with a lot of movement.

HEGEMIP electromagnetic protection sleeves consist of a material mix of halogen-free polyester (abrasion protection yarn) and tinned copper (shielding yarn). This combination delivers shielding whilst reducing the weight in contrast to full metal content shielding sleeves.

More benefits:

In addition to the standard type, HEGMIP wire shielding sleeving is also available in the following special variants:

Twist-In self-closing polyester sleeving is perfect for installation on pre-terminated wiring or retro fitting. It can be opened with a single movement and the bundle is always easily accessible for maintenance, repair and inspection.

Twist-In guarantees easy, simple cable bundling as well as removal without having to disassemble connectors or fittings. With its very good abrasion protection, Twist-In is often used in the production of industrial machinery, electronics, electrical engineering and in the automotive industry – but also as wire protection for home office and entertainment systems.

Twist-In is available in practical 2 m and 5 m lengths. For environments where high fire protection is required, the flame retardant protective Twist-In-FR is the sleeve of choice.

HELAHOOK is a woven cable sleeve with hook-and-loop closure, which perfectly matches the bundling thanks to its elasticity. The wrap-around sleeve can be closed and reopened at any time, which makes it ideal for retrofitting.

Because it is reusable, it is also ideal for temporary use.

This sleeving is used in following areas of application:

The extremely tear and abrasion resistant HEGWS is especially designed for the protection of hydraulic hoses.

HEGWS protects equipment and the people working in close proximity to earth-moving machinery and in applications with mechanical vibration where injection injuries from high pressure pinhole leaks or hose ruptures can occur.

This enclosed polyamide braided sleeving meets DIN EN ISO 3457 and DIN EN 1299.

Braided sleeves help you to organize and bundle cables and wires. But that's not all: They also guarantee electromagnetic shielding and protection at the same time.

Sleeving is available in a variety of materials and with a wide variety of properties for different applications: from flame-resistant braids to burst protection sleeves for hydraulic hoses to EMI shielded sleeves.

While standard solutions are used at home and in IT environments, braided sleeving with special properties is used in almost all industries – including the automotive and rail industries and the defence aerospace industry.

Due to their flexibility, most braided sleeves can easily be pulled over bundled goods manually by the push- and slide method. With the help of a suitable tool, you can simply cut your fabric sleeve to the right length (see details below).

HellermannTyton wire mesh cable braids are supplied with a removable inner tube that makes it easier to push the sleeving over wire harnesses.

In contrast to tubular braided sleeves, there are also wrap-around braided sleeves. These are particularly suitable for speedy installation, but also for retrofitting. HellermannTyton offers slit sleeves with a hook and loop closure, such as HELAHOOK, and self-closing sleeving such as Twist-In.

If you cut braided sleeving with conventional scissors, the ends will most likely fray. This is why for low to medium quantities the use of a hot knife is recommended. With tools like the industrial hot knife HSG0 you can cut braided sleeves cleanly – without any fraying.

Within a few seconds the cutter is ready for use – all it takes is the push of a button. The metal knife is heated, cuts through the sleeve and at the same time ensures that the cut filament ends melt.

Despite its robustness, the braided sleeving hot cutting tool HSG0 is very light and handy.

For high volume applications we offer customized cut length products. Please contact us for an individual offer.