Cable ties have to meet a broad range of requirements because they are used in a wide variety of applications – from the simple bundling of cables with cable ties to very specific uses of cable ties under extreme conditions.

HellermannTyton offers a comprehensive portfolio of fastening solutions for all industrial demands: reusable cable ties for temporary fastening, coloured cable ties for colour coding, cable ties with fixing elements for attachment to plates, weld studs, panel edges or stainless steel cable ties for harsh environments.

Get an overview of our various zip tie solutions here on this page.

HellermannTyton zip ties are available:

In a variety of sizes, with inside serration, outside serration or without serration, in different colours, made of 100% high-quality plastic – easily applied by hand or with a processing tool.

Special cable ties that HellermannTyton offers include:

The metal detectable MCT series was specially developed for use in the food, beverages and pharmaceutical industries. It is ideal for the installation of wiring in and around open production lines.

MCT cable ties are manufactured in a unique process that involves the addition of metal particles to the plastic resin. This makes it possible to detect even small, cut-off sections of the cable tie with commercially available metal detectors.

These zip ties can be used to help meet HACCP requirements. The colour of the zip ties supports visual recognition, further reducing the risk of contamination.

Peek cable ties for high temperature applications are specially designed for the most demanding environments. They are popular in the aerospace, railway, offshore, power, medical engineering and automotive industries. PEEK thermoplastic advantages at a glance:

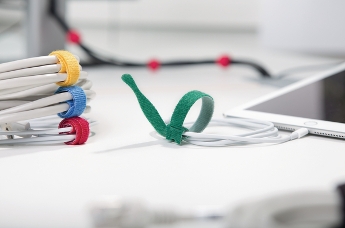

Many applications require a temporary fastening solution: for example, in stage construction, at trade fairs or when bundling telephone, fibre optic and network cables. Reusable cable ties can be easily opened and closed after installation. They are also available with very flexible characteristics. An application example is the securing of tree saplings to supports in gardening and landscaping.

Reusable zip ties are available in different designs, materials, lengths, colours and locking mechanisms: lever, side lock, flexible rubber closure, hook-and-loop or wing release.

Reusable zip ties are available in different designs for a broad range of applications. Get an overview and see how they work – in this video:

The "soft" TEXTIE is ideal for use around telephone cables, fibre optic cables and network cables. In addition, these hook-and-loop material ties are perfect for use in temporary installations such as stage construction or prototype cable harnesses.

TEXTIE can also be used in many household and office applications. It is quick and easy to process by hand and can be reused up to 400 times. Hook-and-loop ties are suitable for both indoor and outdoor use and are available in different colours and sizes.

The ORF series with lever lock has been designed for easy removal and reuse without a knife or side cutter, but conveniently with a lever.

In addition to different sizes and the colours white and yellow, the ORF series also includes a black UV-resistant variants for outdoor use.

The classic black cable tie is still one of the most popular cable ties. But HellermannTyton also offers customers a wide variety of zip ties in different colours – including red, green, brown, white and transparent.

These zip ties are ideal for colour coding: For example, workers can be helped to find certain parts more quickly or to assign them precisely. This plays an especially important role in the automotive sector but also in lots of other industries.

By the way, some industries prefer certain cable tie colours: In the food industry, for example, the colour blue is often preferred, while pink plays an important role in the aerospace sector.

One of many reasons why HellermannTyton offers abroad range of coloured cable tie solutions.

LPH cable ties with flat heads take up little space and are therefore the ideal choice for tight installation conditions. But also wherever injury risks need to be minimised: for example on children’s play equipment where foam cushions are fastened to supports and railings.

Thanks to rounded edges and a flat head, children can play safely without getting caught on a protruding cable tie head. Plus, the outside serration ensures that the soft foam padding is not damaged when the zip ties are tightened.

Low-profile head cable ties are available in various colours: in addition to red, green and brown, the PE400 zip ties for example are also available in natural (transparent) and black.

Learn more about low profile cable ties for playgrounds and suitable accessories.

Wherever safety regulations are high and the reduction of smoke and hazardous fumes is required, the white T-series cable ties made from PA66V0 material are the ideal choice.

Thanks to its compound properties they significantly reduce the development of toxic gases and corrosive acids in the event of fire. In addition, their PA66V0 material meets UL94 V0 requirements.

With their high safety level, these cable ties are particularly popular in the public sector – especially in the railway, construction and defence industries.

Many industrial applications require bundled cables, wires, pipes and hoses to be directly attached to a panel or frame edges. HellermannTyton offers various one-piece and two-piece fastening solutions for round and oval holes, bolts and edges – in various sizes, orientations and colours.

Cable ties with specialised fastening elements are frequently found in vehicles and machinery, for example:

Many applications include round and oval holes to ensure reliable cable routing at predetermined fixing points. The zip tie and fastener are pre-attached to the wiring harness. The foot part of the fastener can then be easily inserted into these holes during final assembly.

A diverse range of mounting solutions is available for almost any hole size and panel thickness. Application can be simply done by hand, without the need for special tools. The

secure locking can be heard and felt by the user with a "click".

Fixing ties with weld stud mounts are primarily used in the automotive industry.

However, they are also used in all other areas where cables and wires have to be guided safely by means of weld studs or threaded bolts.

These ties are available with fixed heads (with a defined position) as well as with flexible heads (with room to move).

In addition to fastening solutions for plates and weld studs, HellermannTyton also offers cable ties with fixing elements for edges.

Learn more about the different applications where EdgeClip solutions are suitable on the cable clips for edges Competence Page.

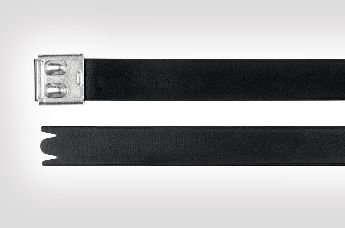

Steel zip ties are recommended for applications requiring extreme tensile strength or extreme material requirements under harsh conditions. They guarantee maximum safety and fire resistance during the toughest emergencies.

It is often necessary to use metal cable ties where chemicals are in use. High grade stainless steel guards against corrosion damage. As a result, stainless steel cable ties are commonly found on ships, in tunnels, mines and throughout the petrochemical industry.

The rustproof MBT stainless steel cable ties resist acids and high temperature. They are ideal for applications where additional safety, high tensile strength and fire resistance are required.

Their patented, non-releasable locking mechanism with one or two balls is a major safety feature.

This zip tie series is often used on data and fibre-optic cables as well as for applications in theatres or at fairs.

Metal cable ties with a polyester coating in SS316 (V4A) stainless steel have the same advantages as the MBT series, but thanks to their coating, they guarantee improved installation comfort at low temperatures.

In addition, the plastic coating is particularly suitable for sensitive bundles and to prevent contact corrosion.

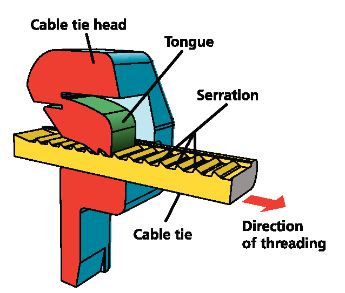

Cable ties work rather like a belt, where the end is passed through a buckle and fastened with a prong inserted through a hole in the strap. In the case of most conventional zip ties, the strap is passed through a head that includes a flexible tongue which glides over teeth, or serrations, moulded into the strap to prevent it slipping backwards, once applied.

This mechanism is used in 90% of all polyamide (PA) cable ties made by HellermannTyton. In order to cover a variety of applications, there are different variants of this system, for example: releasable versions, in-line versions, open head versions.

These are one-piece cable ties. Here, the pawl, or tongue, is moulded as an integral part of the head. This gives it inherent strengths.

Positive locking is achieved by engaging the tongue with the strap serrations when it is pulled through zip tie head.

The KR cable tie series is distinguished by its smooth strap and unique locking mechanism. Here a fibreglass pin is pushed into a membrane in the strap, to hold it in place.

The chamfered, rounded head means the KR zip ties fits very firmly around the bundled material and does not move under vibration.

Made of stainless steel grades 304 or 316, the MBT range of cable ties have no serrations on the strap and are threaded parallel through the head, gliding under a metal ball-bearing locking mechanism which wedges in place when the strap tries to move in the opposite direction

Polyamides are among the most important synthetic thermoplastic materials. Thermoplastics can be reshaped by heating as often as required without undergoing chemical decomposition or other negative changes. This makes polyamide ideal for processing via injection moulding into high quality products.

Around 90% of cable ties and fixings from HellermannTyton are made from this material. Polyamide is also known under the brand name of Nylon®, which was introduced by the Dupont company in 1937.

Polyamide PA66 has many properties which are highly advantageous for HellermannTyton cable ties and fixings, such as:

A wide range of polyamides and additives allows for optimum adaptation of the characteristics of the finished product to suit the respective requirements.

Always store cable ties in the sealed plastic bag made of polyethylene. Once opened you should use the zip ties as quickly as possible to ensure optimal application results. If ties become brittle, they can fail when applied.

Do not expose cable ties to direct sunlight! Do not store cable ties in sunlight; for example, on the windowsill!

Store cable ties away from direct sources of heat. Avoid contact with heat: for example, do not place on the radiators!

The ideal storage conditions for zip ties are those of the central European standard climate:

For optimum handling of cable ties it is important that the material is in a condition of equilibrium with a water content of approximately 2.5%.

The minimum tensile strength is a critical selection criteria for cable ties. It expresses how much loading a cable tie can bear. This minimum tensile strength of a zip tie is determined in accordance with the Military Specification and Standards of the USA. Test conditions being laid down precisely in MIL-S-23190E:

The test procedure to determine minimum tensile strength of a cable tie:

The cable tie is fixed onto a split mandrel test probe with the suitable cable tie application tool.

The mandrel is opened at a defined speed.

The loading at which the zip tie fails is determined.