Heat shrinkable tubing adhesive lined

Art.-Nr. 318-00001

| TA46-5.75/1.25-50mm-PO-X-BK

|

Copied

This product is not available anymore.

- High 4:1 shrink ratio to cover various diameters and profiles

- Semi-rigid jacket offers mechanical protection against abrasion, cutting and bending

- EVA based adhesive for efficient environmental sealing

- Insulating, protecting and sealing in one process step

- Suitable for processing in automated heat shrink application equipment

- Continuous operating temperature -40 °C to +125 °C

- Excellent strain relief due to combination of tough outer jacket and highly efficient adhesive

Request your individual offer now

Request quote

More products in this product group:

| Application | TA46 heat shrink tubing is designed for insulating, sealing and protecting inline wire splices, wire bundles, terminals and connectors. The adhesive lined heat shrink tubing provides moisture proof environmental sealing of electrical splices in wire harnesses especially complying to automotive industry requirements. Besides electrical insulation, the self-extinguishing polyolefin jacket provides mechanical protection against abrasion, cutting and bending. The highly viscous EVA based adhesive once heated, flexibly flows between wires or conductors. The combination of excellent adhesive bonding properties and strong jacket shrink performance provides excellent bonding to cable jackets and environmental sealing of complex profiles. |

| Application Method |

The pre-cut tubing is positioned on top of the splice area or to be insulated product. When heating the tubing, the adhesive starts melting and flowing around the cable splice and welded wires as well in between the individual wires. The shrinking outer jacket is squeezing the adhesive along the splice area and between individual wires to both ends of the tubing finishing the environmental seal. TA46 can be processed on heat shrink application equipment used for semi or full automated production line set-ups whether in pre-assembly or wire harness production lines. |

| Behaviour At Low Temperature | not cracking |

| Behaviour at Heat Shock | not cracking, not dripping |

| Behaviour at low Temperature test method | UL 224 |

| Colour | Black (BK) |

| Elongation At Heat Aging | 220% |

| Heat Aging Test | 168h/158°C |

| Heat Aging test method | ASTM D2671 |

| Heat Shock Test | 4h/225°C |

| Heat shock test test method | ASTM D2671 |

| Material | Polyolefin, cross-linked (PO-X) |

| Minimum Tensile Strength At Heat Aging | 12MPa |

| PART DESCRIPTION | TA46-5.75/1.25-50mm-PO-X-BK |

| Package Content packed in | bag |

| Printable | No |

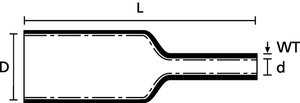

| Product Family | TA46 - thin wall, 4:1 shrink ratio |

| Product Group | Heat shrinkable tubing adhesive lined |

| Shrink Ratio | up to 4:1 |

| Type | TA46-5.75/1.25-50mm |

| Variant | Thin-Wall |

| With inner glue (Yes/No) | Yes |

| Adhesive | Hot melt adhesive |

| Dielectric Strength | 10kV/mm |

| Dielectric Strength test method | IEC 60243 |

| Elongation at break | 500% |

| Elongation at break test method | ASTM D2671 |

| Flammability | ASTM D2671 |

| Halogen-free | No |

| Min. Shrink Temperature - °C | +110 °C |

| Operating Temperature | -40 °C to +125 °C |

| ROHS compliant | Yes |

| Specifications |

|

| Tensile Strength | 12MPa |

| Test Method Tensile Strength | ASTM D2671 |

Argentina

Argentina Australia

Australia Brazil

Brazil Bulgaria

Bulgaria China

China Czech Republic

Czech Republic Denmark

Denmark Finland

Finland France

France Germany

Germany Hungary

Hungary India

India Italy

Italy Netherlands

Netherlands North America

North America Norway

Norway Poland

Poland Portugal

Portugal Romania

Romania Russia

Russia Singapore

Singapore Slovenia

Slovenia South Africa

South Africa South Korea

South Korea Spain

Spain Sweden

Sweden Switzerland

Switzerland Türkiye

Türkiye United Arab Emirates

United Arab Emirates United Kingdom

United Kingdom

Download

Download

H6100

391-00110

H6100

391-00110 TA46-5.75/1.25-PO-X-BK

318-00000

TA46-5.75/1.25-PO-X-BK

318-00000